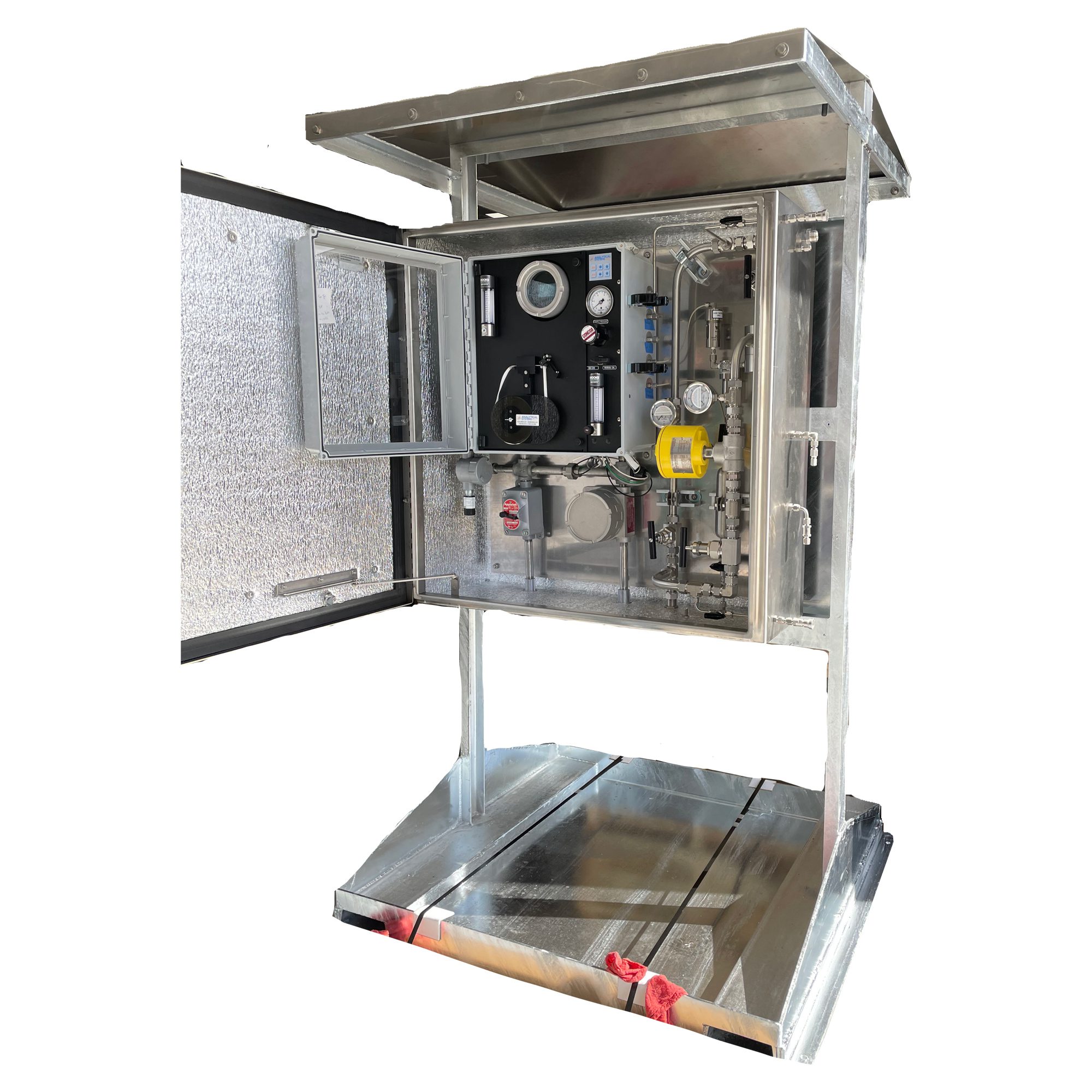

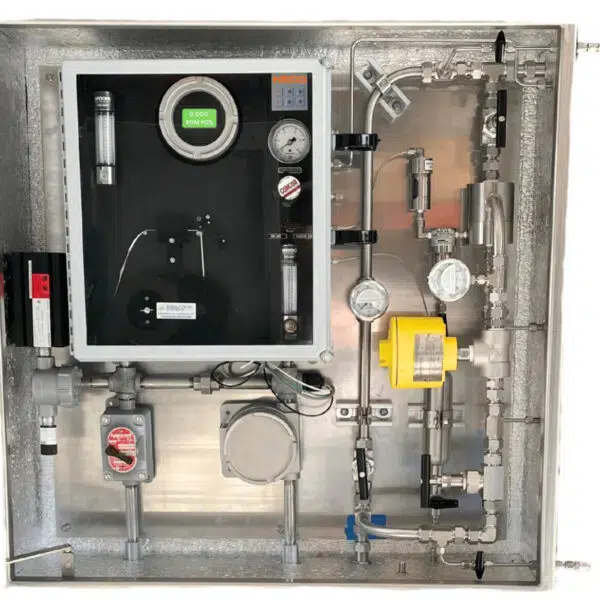

H2S in Liquids Process Analyzer

Features

Features

- Real-time and accurate measurement

- Measure H2S in crude, water, diesel, etc.

- Specific to H2S only, no false positives ever

- No field calibrations required

- No liquid sample conditioning required

- No sample filters required

- Only one tap-point needed for sample exit and return (when pitot probe is utilized)

- Fast response time

- Proven reliability

- Conformity to ASTM methods

- Set in-line at process pressure and flow

Description

Product Description

The effective procedure to measure H2S in crude oil and other opaque liquids requires the representative stripping of the H2S from the liquid into the gas phase for analysis by a gas H2S analyzer or sensor. Traditionally, headspace stripping columns have been used for this purpose but have become infamous for being problematic, high maintenance, and requiring many moving parts that break down over time.

KECO has overcome the shortfalls of the headspace stripping column by developing a reliable alternative; the state-of-the-art PermaStream utilizing KECO Membrane Technology. The PermaStream efficiently and reliably separates the H2S from the liquid sample for measurement in the gas phase by the H2S analyzer which is specific only to H2S and does not su er from false positives. The PermaStream is a simple device that continuously provides an ultra-clean and dry sample to the H2S sensor. This results in radically reduced maintenance when compared to the headspace stripping column.

KECO is established as the world-wide leader in H2S in liquids analysis online due to the many bene fits of PermaStream’s exclusive technology. The 205 PermaStream is capable of measuring in ppb, ppm or even precent ranges and will never su er from false-positives like other H2S detection methods.