H2S in Condensate Analyzer

Features

Features

- Save on lab analysis costs with unattended online analysis with this online hydrogen sulfide analyzer for condensate

- Economical: Quick analyzer payout by real-time data ensures high efficiency of the process

- Easy: Field calibrations are not required

- Safe: Hazardous area ratings for Zone 1 or Zone 2 (Division I or II), ATEX and IECEx certification may be available (added cost)

- Accurate: Grab samples for the lab deteriorate with time, H2S escapes during sampling. The Model 205 measures continuously.

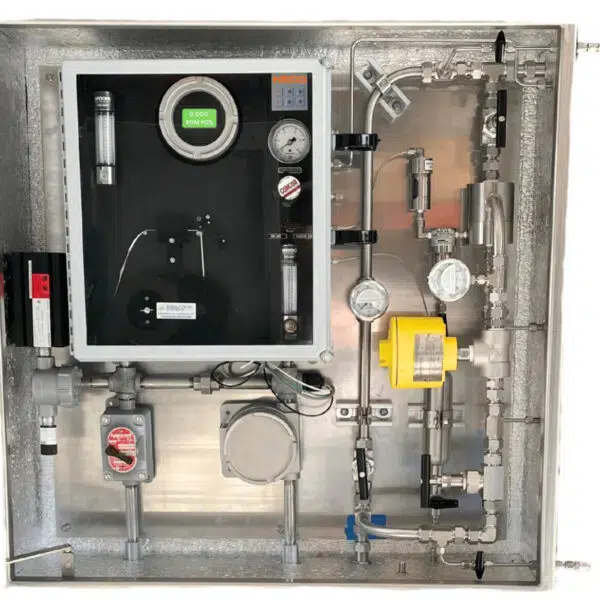

- Dependable: The exclusive Sample Transfer Stripper™ for sampling radically reduces maintenance by ensuring a clean, dry sample to the detector.

Description

Product Description

The ability to analytically quantify hydrogen sulfide in condensate is enhanced with the Sample Transfer Stripper in our H2S in Condensate Analyzer, exclusive KECO Membrane Technology and ratiometric colorimetric technologies offered by KECO. This principle of operation is described in various ASTM methods including D4084-82, D4468-85, and D4045-81.

The process of measuring hydrogen sulfide in condensate samples is to representatively separate the hydrogen sulfide from the condensate for measurement in the gas phase. The problematic and complicated “Headspace” system, which often suffers from liquid carry-over, is not required for this separation. KECO utilizes the state-of-the-art Sample Transfer Stripper (STS) with exclusive KECO Membrane Technology to efficiently and reliably separate the H2S from the liquid sample. The STS is an extremely simple device that provides an ultra-clean and dry sample to the detector for analysis. The STS uses 90% fewer parts than the complicated “Headspace” method. This results in radically reduced maintenance requirements when compared to the headspace method and also enhances analytical reliability. KECO is established as the world-wide leader in H2S in Condensate analysis due to the many benefits of this exclusive technology.

The principle of operation is based on a continuous, free-flowing liquid sample into the heated Sample Transfer Stripper (STS) unit which separates the liquids from the H2S gas sample, based in part on Henry’s Law. The carrier air then continuously sweeps the H2S sample to the H2S specific detector for quantitative analysis in ppb, ppm, or percent levels. The analyzer does not require zero or span calibrations and is extremely simple to operate and maintain.

The detection technology is based on chemically specific density changes. The advanced lead acetate sensing tape utilized in our analyzers is the only detection method that is absolutely specific to H2S and does not require calibrations in the field. As few as 3-6 tape changes per year are needed. Optical illumination and detection are integrated for maximum resolution accuracy. Economic payout is increased because of this automated and continuous process analyzer. A laboratory version is also available. Patents and Patents Pending based on letters that are available on request.

Applications

Applications

Safety

Transporting condensate in truck or vessel can be life threatening to personnel due to unknown levels of hydrogen sulfide contained in the condensate. An accident could result in serious injury or death. The model 205 eliminates health risks of personnel by safely measuring H2S content in a closed loop system before the condensate is loaded on the truck.

Corrosion Control

Hydrogen Sulfide is corrosive to pipelines, tanks, rails, trucks, FPSO and other holding and transportation vessels. The model 205 will accurately measure H2S levels and allows historical data to help treat the H2S before cost intensive measures must be taken and before accidents occur.

H2S analyzer for condensate.