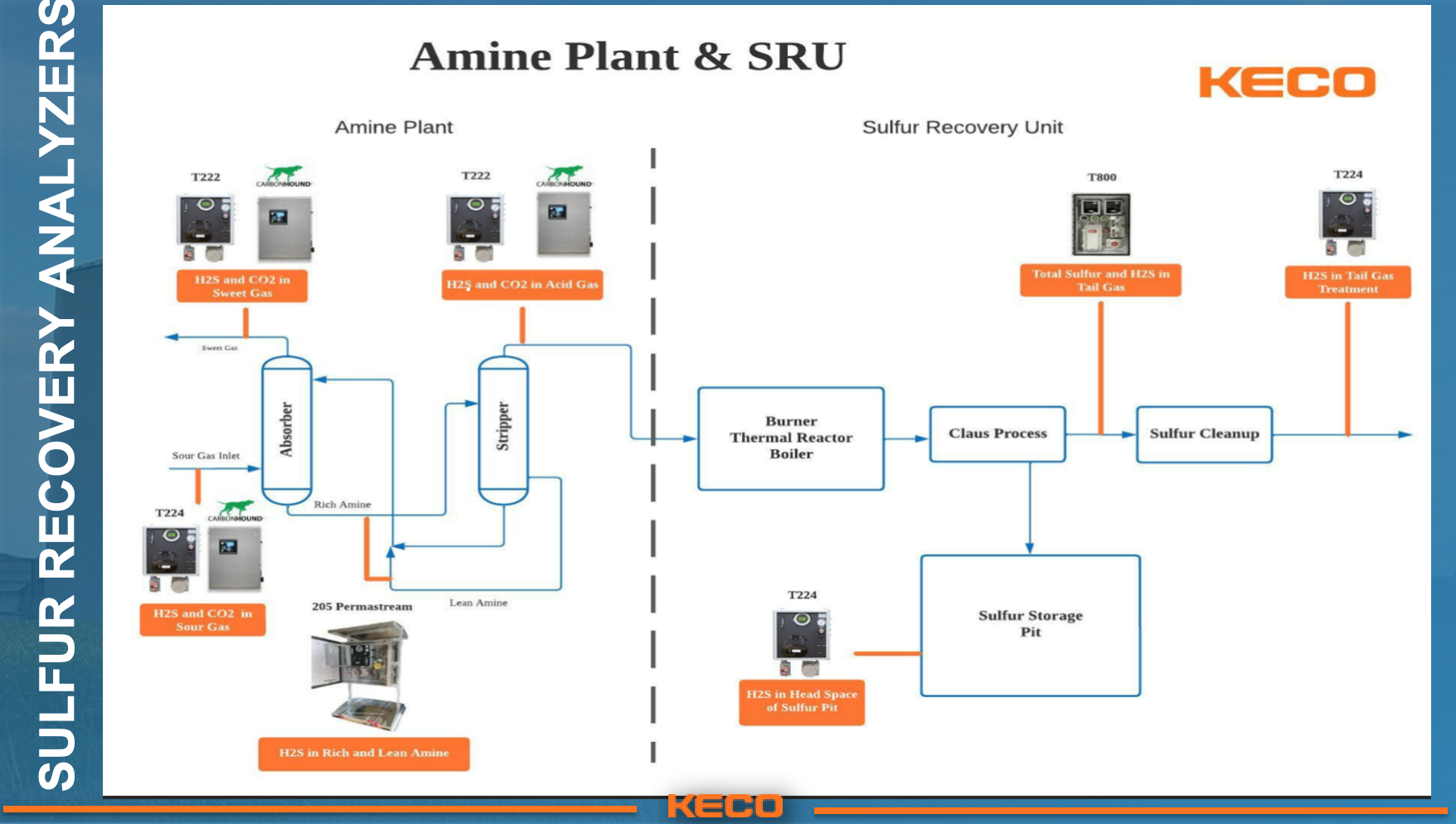

Importance Of Analyzers For Downstream Industries

KECO analyzers play a crucial role in the downstream industry by ensuring precise monitoring of hydrocarbons, sulfur content, and emissions. They help downstream operations maintain regulatory compliance, optimize efficiency, reduce operational risks, and enhance product quality. By providing real-time data, these analyzers enable better decision-making and process control, ultimately leading to cost savings and improved environmental performance.

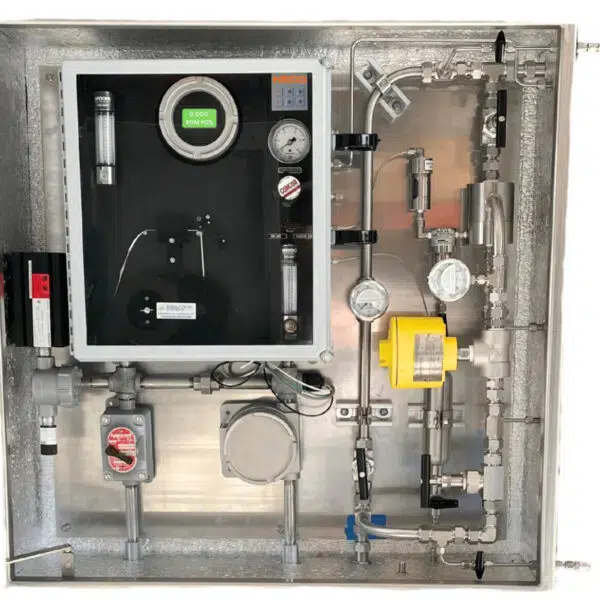

How Our Analyzers Work

Our analyzers utilize advanced sensor technology and proprietary membrane separation techniques to provide accurate and reliable measurements. Designed for real-time process monitoring, they detect key parameters such as sulfur levels, hydrocarbon content, and gas leaks. With minimal sample conditioning required, our analyzers streamline operations, improve efficiency, and ensure continuous compliance with industry regulations.

Applications

Why Choose KECO Analyzers For the Downstream Industry

Our analyzers deliver accurate monitoring, ensure regulatory compliance, and provide cost-effective solutions designed for downstream operations.

Optimized Contaminant Detection

KECO analyzers deliver high-precision detection of critical contaminants such as hydrocarbons, H₂S, and VOCs, ensuring operational safety and product quality across industrial applications.

Regulatory Compliance & Industry Standards

KECO analyzers comply with ASTM-approved methods, ISA standards, and hold BACT certification, ensuring alignment with downstream industry requirements. Our systems are NMAC compliant, TX RRC compliant, ATEX certified, and IECEx certified, confirming their suitability for hazardous environments and global regulatory mandates.

Seamless System Integration

Engineered for compatibility, KECO analyzers integrate smoothly into existing process control and automation systems, enabling efficient data communication and minimal disruption during installation.

Low Maintenance & Long-Term Reliability

Designed for harsh industrial settings, KECO analyzers provide durable, long-lasting performance with low service requirements, reducing downtime and operational costs.

Automated Operation & Remote Access

Featuring automated processes and remote monitoring, our analyzers support real-time data access and diagnostics, improving response times and ensuring consistent regulatory compliance.

KECO Support & Service

A comprehensive maintenance and service program designed to maximize analyzer uptime, reduce operator intervention, and ensure seamless downstream operations.

Explore Our Product Range

What Our Clients Say

Real stories from real partners. See how we’ve made an impact.

Frequently Asked Questions

Find answers to common questions about our analyzers, their applications, and how they enhance efficiency.

Yes. KECO’s analyzers, such as the Model 1700-150, utilize hydrogenation methods aligned with ASTM standards (D3031, D4084-82, D4468-85, and 4045-81) to measure total sulfur content in fuels and finished products.

KECO analyzers provide real-time data outputs (4–20 mA, RS-485 Modbus, and TCP/IP Ethernet) that can be integrated into blending and formulation control systems. This allows for automated adjustments to maintain desired fuel specifications.

Absolutely. KECO analyzers feature advanced Human-Machine Interfaces (HMIs) with color touchscreens and support for remote monitoring via KECO Connect, enabling integration with control rooms and digital dashboards for centralized monitoring and control.

KECO analyzers offer data logging capabilities, storing historical data that can be accessed remotely. This is essential for downstream auditing, providing traceability and compliance documentation.

By continuously monitoring sulfur levels and other contaminants, KECO analyzers ensure that emissions and product specifications comply with environmental regulations, helping operators avoid penalties and maintain operational licenses.

KECO’s analyzers provide real-time measurements of sulfur content, with outputs that can be integrated into reporting systems. This facilitates timely adjustments and accurate reporting for compliance and quality assurance.

KECO offers analyzers with explosion-proof ratings suitable for hazardous areas, such as Class I Division 1 & 2. The Series 1700 is an example, designed for safe operation in explosive environments.

Yes. KECO analyzers feature automatic self-zeroing and can be programmed for automated calibration checks, reducing maintenance requirements and ensuring consistent accuracy over time.

Other Industries We Serve

KECO analyzers support a wide range of industries beyond downstream industry, delivering precision monitoring and compliance solutions for various applications.