Acid Gas Treating Optimization

KECO Solutions For Precise Acid Gas Detection

KECO offers advanced analyzers engineered for accurate, continuous measurement of hydrogen sulfide (H₂S) and carbon dioxide (CO₂) in challenging industrial environments.

Dual H2S & CO2 Gas Analyzer

The KECO Dual H2S & CO2 Gas Analyzer CS Hound is specifically designed for continuous, online monitoring of acid gas components such as hydrogen sulfide (H2S) and carbon dioxide (CO2). It uses electrochemical sensing for H2S and NDIR technology for CO2 detection. The sample gas is regulated to 10 PSI with a controlled flow rate of 1.5 SCFH to ensure precise measurement.

Fugitive Emission Control (Emission Eliminator)

The KECO Fugitive Emission Eliminator is designed to safely oxidize vented process gases, including acid gases like hydrogen sulfide, using a catalytic combustion system that maintains atmospheric pressure reference for analyzers. Operating with a continuous heat source, it converts over 99% of emissions into CO2 and water vapor. Housed in an explosion-proof enclosure, it enables safe deployment in hazardous environments where acid gas monitoring equipment is used.

Learn More About Fugitive Emission Control (Emission Eliminator)

H2S in Gas Analyzer (Electrochemical)

The KECO SulfurHound H2S in Gas Analyzer provides continuous, online detection of hydrogen sulfide within acid gas streams using reliable electrochemical sensor technology. The sample gas is regulated to approximately 10 PSI and maintained at a flow rate of 1.5 SCFH before entering the detection element, which generates a signal proportional to the H2S concentration.

H2S Analyzer

The KECO H2S Analyzer 100 (GP) and 200 (Div 1 & 2) deliver continuous, interference-free measurement of hydrogen sulfide within acid gas streams using the ASTM-approved lead acetate tape method. Sample gas is regulated to 10 PSI and passed through a precision flow meter before reaching a photometric sensor that quantifies H2S concentration. An onboard microprocessor digitizes the signal, providing a linear 4–20 mA output displayed on an integrated LCD with alarms and calibration prompts.

Learn More About H2S Analyzer

CO2 Process Analyzer

The KECO CarbonHound CO2 Process Analyzer provides continuous, online measurement of carbon dioxide, a key component of acid gas streams, using non-dispersive infrared (NDIR) technology. The gas sample is regulated to approximately 1.5 SCFH via a precision flowmeter before entering the IR sensor, which outputs a signal proportional to CO2 concentration. Data is processed by an onboard microprocessor and displayed on a color touchscreen with 4–20 mA output, alarms, and digital communication (RS-485, TCP/IP). Built with materials compatible with acid gas environments, the system ensures accurate, reliable, and low-maintenance CO2 monitoring critical to acid gas analysis and control.

Learn More About CO2 Process AnalyzerH2S + Total Sulfur Analyzer (2 in 1)

The KECO H2S + Total Sulfur Analyzer (2 in 1) is engineered for precise, continuous measurement of hydrogen sulfide and total sulfur levels in acid gas streams. Sulfur compounds are thermally cracked in a hydrogen stream at up to 1,315°C, converting them into H2S, which is then detected via lead acetate tape using optical rate-of-reaction sensing.

Oxygen (O2) Gas Analyzer

The KECO Oxygen (O2) Gas Analyzer employs advanced optical quench luminescence technology for accurate, real-time monitoring of trace oxygen in acid gas streams. Its precise measurements in ppmv are critical for maintaining safe and efficient acid gas treatment and sulfur recovery operations.

Portable H2S Analyzer

The KECO Portable H2S Analyzer provides accurate, continuous measurement of hydrogen sulfide in acid gas streams using interference-free lead acetate tape technology. Compact and battery-powered, it offers a detection range from ppb to 500 ppm and features an optional sample pump for field use. Its advanced optics deliver precise real-time readings with minimal maintenance, making it ideal for on-site acid gas monitoring and process control.

Learn More About Portable H2S Analyzer

Laboratory H2S Analyzer

The KECO Laboratory H2S Analyzer provides precise, interference-free hydrogen sulfide measurement in acid gas samples, ranging from low ppb to high ppm. It uses ASTM-approved lead acetate tape technology for accurate results without false positives. Simple one-button operation delivers fast analysis in 5–10 minutes. Designed for low maintenance, it’s ideal for reliable lab and process monitoring of acid gases.

Learn More About Laboratory H2S AnalyzerTotal Sulfur Analyzer

The KECO Total Sulfur Analyzer delivers accurate, low-maintenance, and cost-effective measurement of total sulfur in gas streams, essential for acid gas monitoring. It uses hydrogenation to convert sulfur compounds to H2S, which is then detected by a lead acetate tape via rateometric-colorimetric technology, ensuring precise readings from ppb to 100% sulfur levels.

Why KECO Analyzers Are Essential For Acid Gas Measurement

KECO analyzers ensure precise acid gas measurement, supporting safe and efficient operations. They enable operators to maintain process integrity, protect infrastructure from corrosion, and ensure personnel safety.

Key Benefits Of KECO Analyzers

- Ensure accurate, real-time acid gas monitoring

- Support regulatory and environmental compliance

- Enhance process efficiency and control

- Minimize corrosion, maintenance, and downtime

- Enable safe, reliable plant operation

Advanced Technology For Reliable Acid Gas Analysis

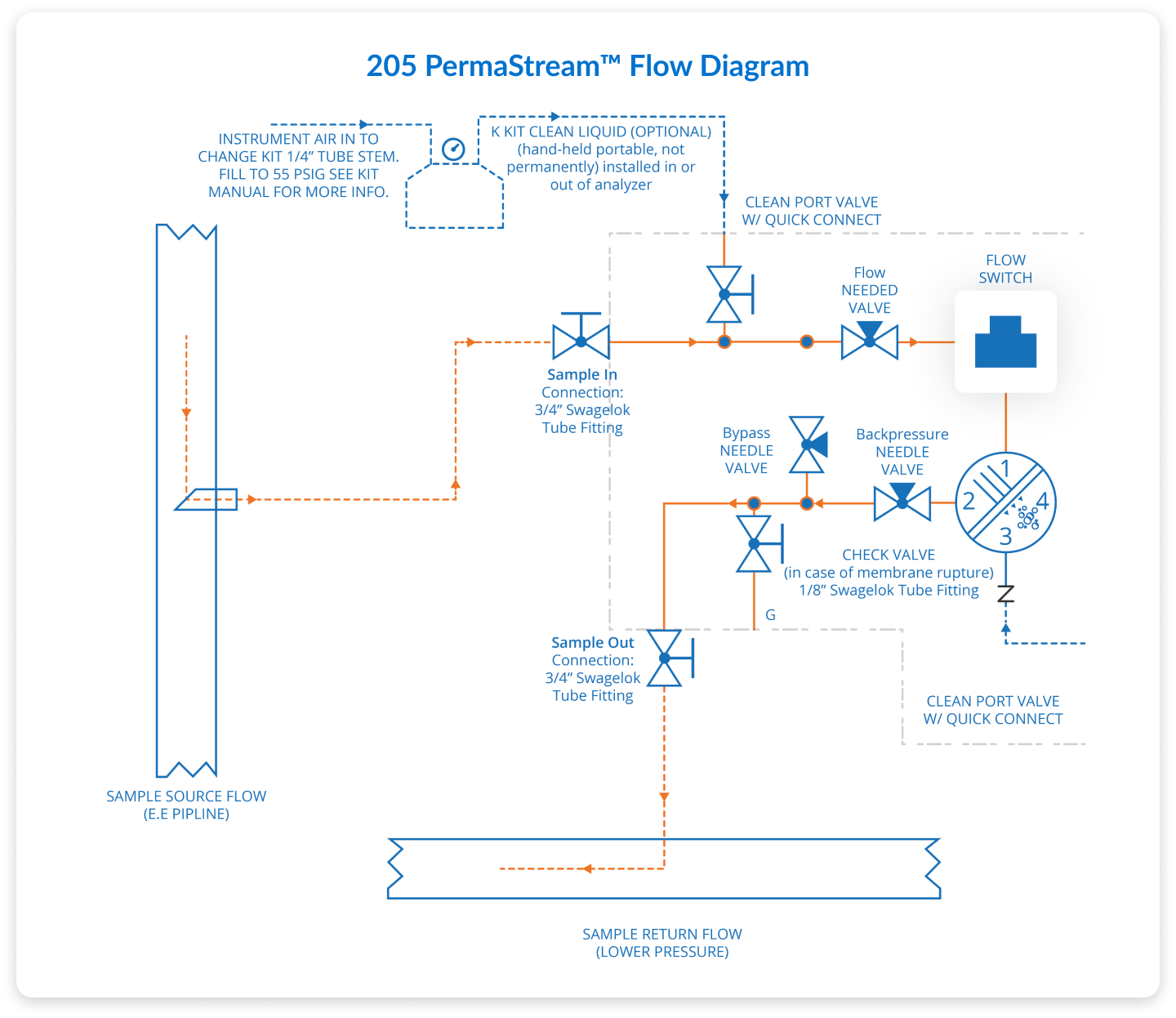

KECO analyzers use electrochemical sensors for selective hydrogen sulfide detection and NDIR sensors for accurate carbon dioxide measurement, ensuring precise, interference-free acid gas analysis. With robust data processing and membrane sampling, KECO provides real-time, reliable monitoring for effective acid gas management.

Achieve real-time acid gas monitoring with proven reliability

Ensure reliable, real-time control before issues escalate. Protect critical operations with fast, accurate monitoring designed for industrial demands.