In the chemical industry, even the slightest variation in composition can affect product quality, safety, and efficiency. Liquid and gas analyzers are essential tools enabling precise detection, measurement, and monitoring of chemical compositions. It ensures quality control, regulatory compliance, and process optimization across various industries handling different chemicals. Whether it's in specialty chemicals, bulk production, or fine chemical synthesis, analyzers ensure consistent, reliable performance in complex manufacturing environments.

How Our Analyzers Work

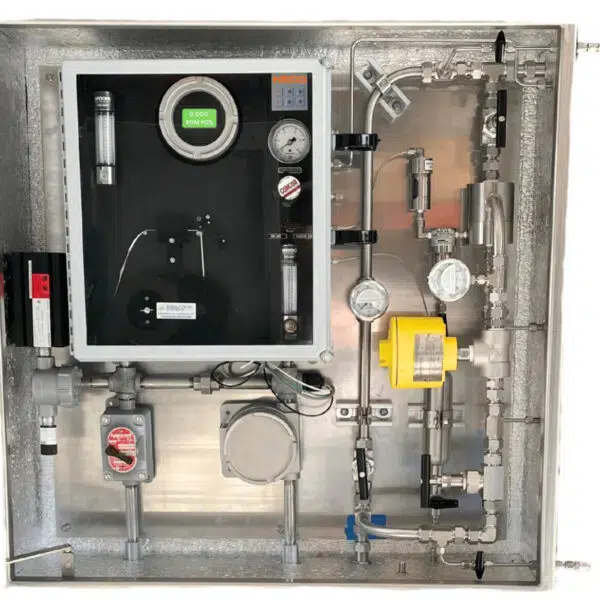

Our analyzers utilize advanced technologies such as spectroscopy, chromatography, and electrochemical sensors to detect, measure, and interpret chemical compositions. These technologies ensure precise gas analysis, enabling reliable monitoring and compliance with environmental standards.

Applications

Why Choose KECO Analyzers For the Chemical Industry

KECO’s chemical analyzers stand out for their accuracy, reliability, and advanced technology, ensuring precise chemical composition analysis across various industrial applications. Designed to support regulatory compliance, operational efficiency, and safety, our analyzers provide real-time monitoring and long-term performance for critical processes.

Optimized Contaminant Detection

Our analyzers deliver precise, real-time detection of key contaminants, supporting improved safety, process control, and environmental protection.

Regulatory Compliance & Industry Standards

KECO analyzers help industries meet stringent environmental and safety regulations, ensuring compliance with EPA, OSHA, and other industry standards. They are NMAC compliant, TX RRC compliant, ATEX certified, and IECEx certified, offering accurate and consistent chemical monitoring in regulated environments.

Seamless System Integration

Our analyzers are designed for easy integration with existing control systems, enabling smooth data transfer, real-time analytics, and enhanced process efficiency without major infrastructure changes.

Low Maintenance & Long-Term Reliability

Built for durability in demanding environments, KECO analyzers require minimal upkeep and deliver reliable, long-term performance, reducing operational costs and downtime.

Automated Operation & Remote Access

Featuring automated functions and remote connectivity, our analyzers allow real-time monitoring, diagnostics, and control, ensuring continuous compliance and operational oversight from virtually anywhere.

KECO Support & Service

We provide dedicated customer support, maintenance services, and expert assistance, ensuring your analyzer operates at peak performance for long-term reliability and compliance.

Explore Our Product Range

What Clients Are Saying About Our Analyzers

Hear from industry professionals who rely on KECO analyzers to meet strict compliance standards, cut operating costs, and streamline their processes with confidence.

Frequently Asked Questions

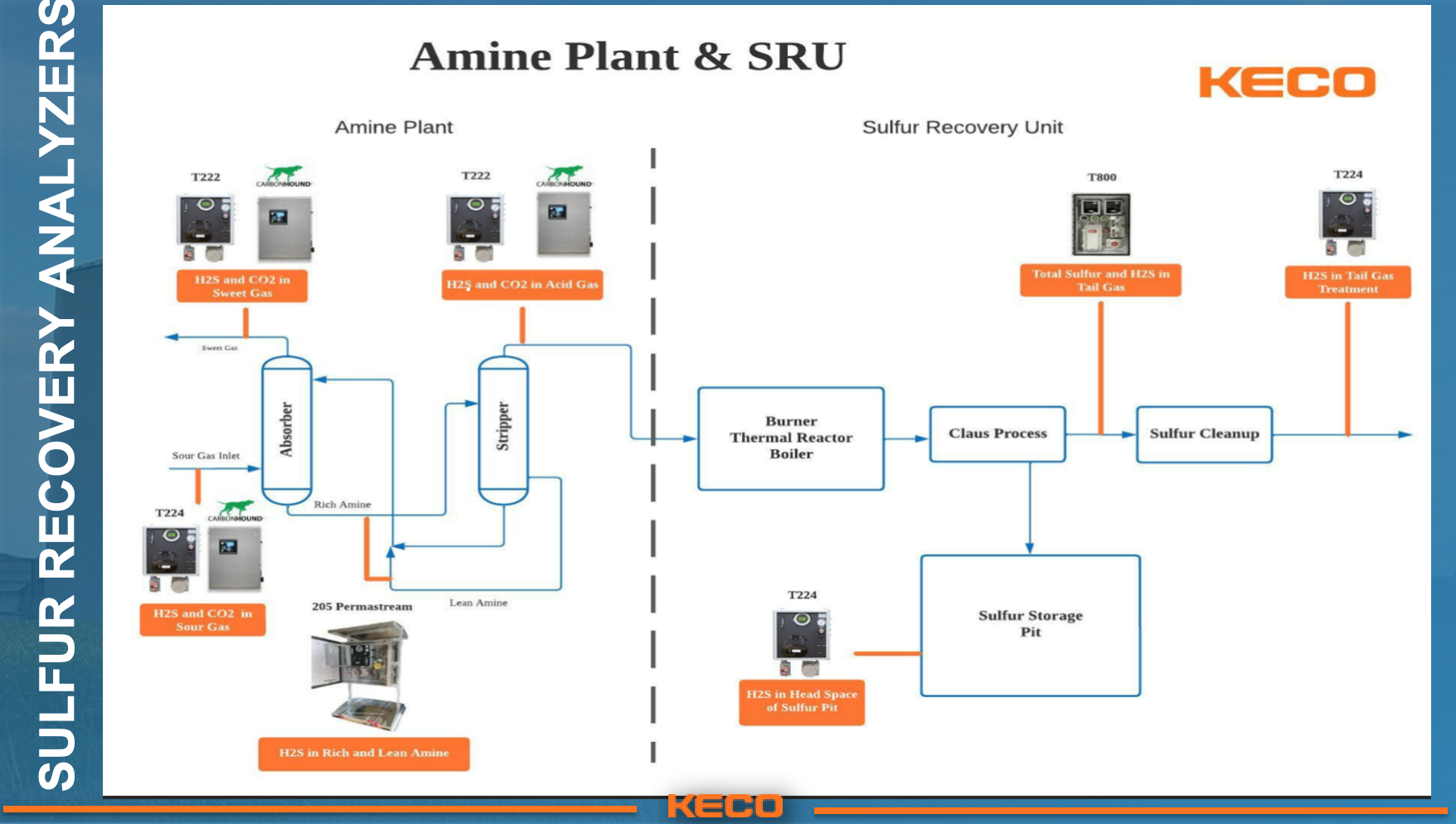

In chemical manufacturing, KECO analyzers monitor key gases to ensure safety and process efficiency. They detect hydrogen sulfide (H₂S) to prevent corrosion, volatile organic compounds (VOCs) for environmental compliance, carbon dioxide (CO₂) to control combustion processes, and oxygen (O₂) to maintain safe operating conditions. These analyzers are built for reliability in demanding industrial environments.

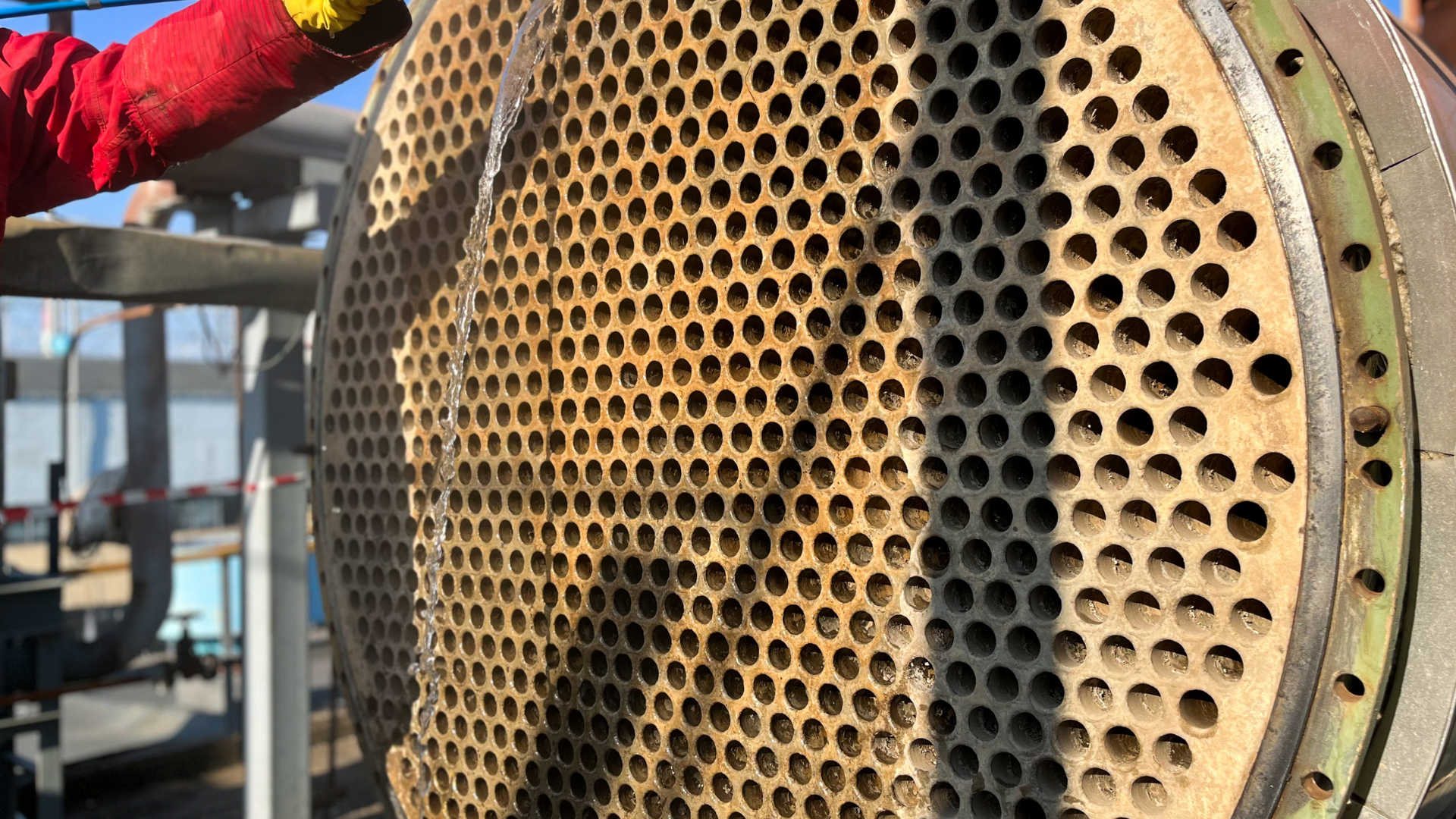

Yes, KECO analyzers are designed to withstand corrosive environments commonly found in chemical manufacturing. They utilize chemical and corrosion-resistant coatings, such as Ethylene ChloroTriFluoroEthylene (ECTFE), which provide excellent resistance to strong acids, chlorine, and aqueous caustics, operating effectively at temperatures up to 300°F (149°C).

For VOC detection, the Model 204 Hydrocarbon VOC in Water Analyzer is ideal. It employs KECO’s proprietary membrane technology to accurately quantify total hydrocarbons and VOCs in various water sources, including cooling towers and wastewater .

For H₂S detection, the H₂S Gas Analyzer offers precise measurement using a rateometric-colorimetric tape detector, which is free from cross-interference and false positives .

KECO analyzers are engineered to function effectively in high-temperature environments. Their components and coatings are selected to withstand elevated temperatures, ensuring reliable performance in various industrial settings.

Real-time monitoring with KECO analyzers enables immediate detection of process anomalies, allowing for prompt corrective actions. This proactive approach minimizes the risk of unplanned shutdowns, enhances safety, and ensures continuous compliance with regulatory standards.

KECO analyzers are designed to meet industry standards and certifications required for use in chemical plants. While specific certifications may vary by model, KECO ensures that their analyzers comply with relevant safety and performance standards applicable to chemical manufacturing environments.

KECO analyzers are equipped with advanced detection technologies that allow for accurate analysis of mixed gas compositions. For instance, the Dual H₂S & CO₂ Gas Analyzer can simultaneously measure hydrogen sulfide and carbon dioxide levels, providing comprehensive monitoring of complex gas streams .

Yes, KECO systems can be integrated with nitrogen or inert gas purging systems to enhance safety. Purging with inert gases helps prevent the accumulation of flammable or hazardous gases within the analyzer, reducing the risk of explosions or contamination.

Other Industries We Serve

Explore other industries where our cutting-edge analyzers deliver proven performance and reliability.