Ensuring Accuracy With The Right Oil in Water Monitors

March 21, 2018

Many widely used oil in water monitors in service today only detect a fraction of hazardous hydrocarbons in water samples, leaving many hydrocarbons un-monitored and contributing to pollution issues around the world.

Other oil in water monitors offer a total hydrocarbon measurement including aromatic and aliphatic hydrocarbons and results in more accurate readings.

It is important to understand the fundaments differences between the oil in water monitors available before choosing to purchase a monitor.

Unfortunately, the widely used oil in water monitors utilizing fluorescence technology faces serious drawbacks in terms of sufficiently monitoring water for presence of hydrocarbon leaks. The popular fluorescence technology based oil in water monitors emit a light on the water sample. The light is typically in the ultra-violet light spectrum, or in the IR spectrum.

How Fluorescence Technology Works

The popular fluorescence technology based oil in water monitors emit a light on the water sample. The light is typically in the ultra-violet light spectrum, or in the IR spectrum. Aromatic hydrocarbons get excited by this light and “fluoresce”.

A detector, typically a spectrometer or photometer detects the excitation of the aromatic hydrocarbons and attempts quantify the concentration, typically using ppm engineering units. Several drawbacks exist with the fluorescence method of detection.

False Positives From Non-Polluting Elements

Many non-polluting elements found in water sources may be fluoresced, causing a false positive. Particulate in water such as turbidity may include liquids and solids such as clay, wood, dirt, plankton, algae, and bacteria.

Attempts have been made to reduce the interference by filtering the water before analysis, however these elements are difficult to filter completely and effectively.

Clay particles can even pass through a one micron filter.

Erroneous Results from Inorganic Materials and Gases

Inorganic materials and gases may absorb giving erroneous results as well.

Naturally occurring bubbles in the water also give erroneous readings.

Undervalued Readings from Aliphatic Compounds

Furthermore, straight chain VOCs and aliphatic compounds typically do not respond with the UV Fluorescence methods, causing undervalued readings which can cause more problems than false positives.

Ineffective Solutions to Fluorescence Limitations

Optional filters are used in an attempt to correct the problem of interference but produce little results. Filtering also results in ‘scrubbing’ of critical oil components that need to be quantified. A large surface sensing area of the sample is used in attempt to increase accuracy, but this does not correct the problems associated with turbidity.

Oil hydrocarbons may still hide behind solids and evade measurement.

This results in inaccurate readings. In addition, selective light filtering techniques, which use specific wavelengths, are used in attempt to increase accuracy and sensitivity.

This technique is also highly sensitive to anything in addition to VOCs and oil molecules, such the aforementioned contamination. As a result, output readings including zero may be unstable. Calibrations may be affected as well. This filtering technique often blocks out important oil molecules critical for accurate and representative measurements.

The Membrane-Sensor Method: A Reliable Alternative

An alternative method to measure total hydrocarbons in the water currently exists.

This method includes a proprietary membrane technology combined with a solid-state sensor housed in a temperature-controlled analyzer cabinet.

How the Membrane-Sensor Method Works

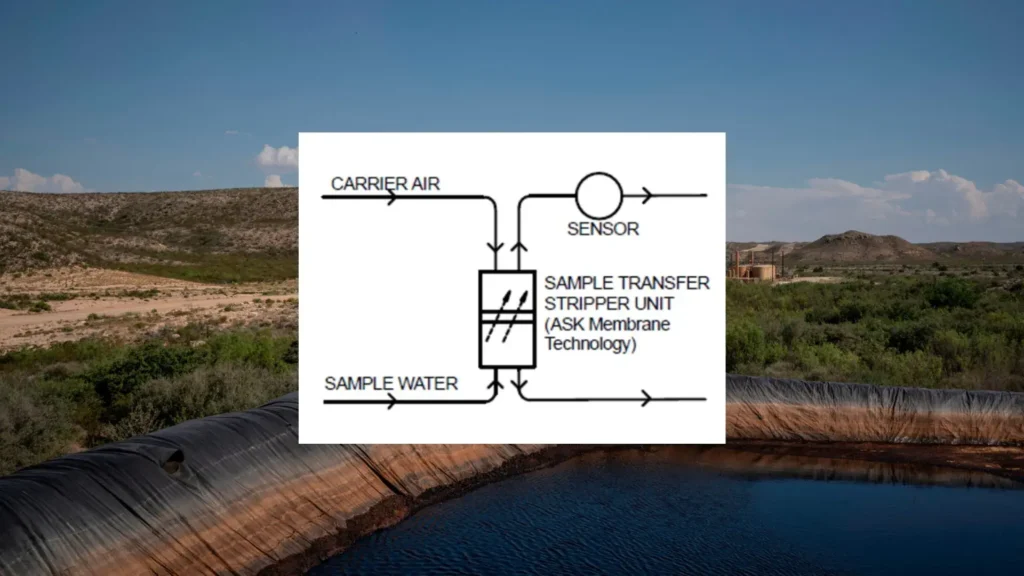

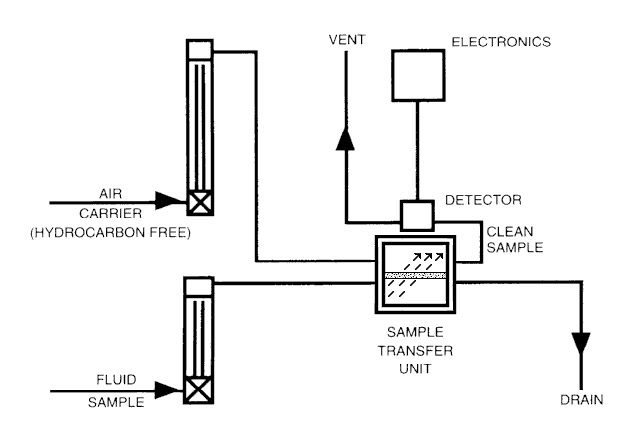

The water sample flows continuously into the analyzer cabinet and past one side of the proprietary membrane and exits out the analyzer drain.

A representative sample of the hydrocarbons in the water permeate thru the membrane where a carrier air sweeps the sample to the solid-state sensor for quantification.

Simplified flow diagram of the membrane-sensor oil in water monitor method

Unlike fluorescence methods, the membrane-sensor method detects both aromatic and aliphatic hydrocarbons, giving the user a complete picture of polluting hydrocarbons in the water sample.

Why Choose the Model 204 Analyzer

Analytical Systems Keco (ASI KECO) is the only company that has developed and incorporated the principles of the membrane-sensor method in the Model 204 analyzer.

In summary, the use of the membrane-sensor technologies offered in the Model 204 is recommended considering the many interferences, inaccuracies & maintenance requirements of the fluorescence and turbidity methods.

Please contact ASI KECO for more information.

Request a Budgetary Quote for Your Application

Provide your project specifications, industry details, and end-use location to receive a tailored pricing estimate from our team.

Request Budgetary Price