KECO Oxygen Trumps Traditional Electrochemical Analysis for Oxygen Measurement in Gas

December 11, 2024

In the ever-evolving landscape of industrial gas monitoring, precision and reliability are paramount. KECO, a leader in innovative gas detection solutions, recently conducted a field trial of its OxyHound oxygen analyzer, demonstrating a significant leap forward in oxygen measurement technology.

This trial, conducted in collaboration with a leading Vapor Recovery Unit (VRU) manufacturing company, highlighted the advantages of KECO’s luminescence-based OxyHound over traditional electrochemical analyzers.

The Challenge: Overcoming Limitations Of Electrochemical Cells

Electrochemical cells have long been the go-to technology for detecting low levels of oxygen in gas streams. However, these cells are not without their flaws. Frequent maintenance, susceptibility to contamination from liquids, and the high cost of replacement cells make them a less-than-ideal choice for many applications.

Seeking a more reliable and cost-effective solution, the VRU company turned to KECO. Their objective was clear: find an oxygen analyzer that delivers accurate, consistent results with minimal maintenance and long-term cost implications.

The Trial: Head-to-Head Comparison At An Upstream Site

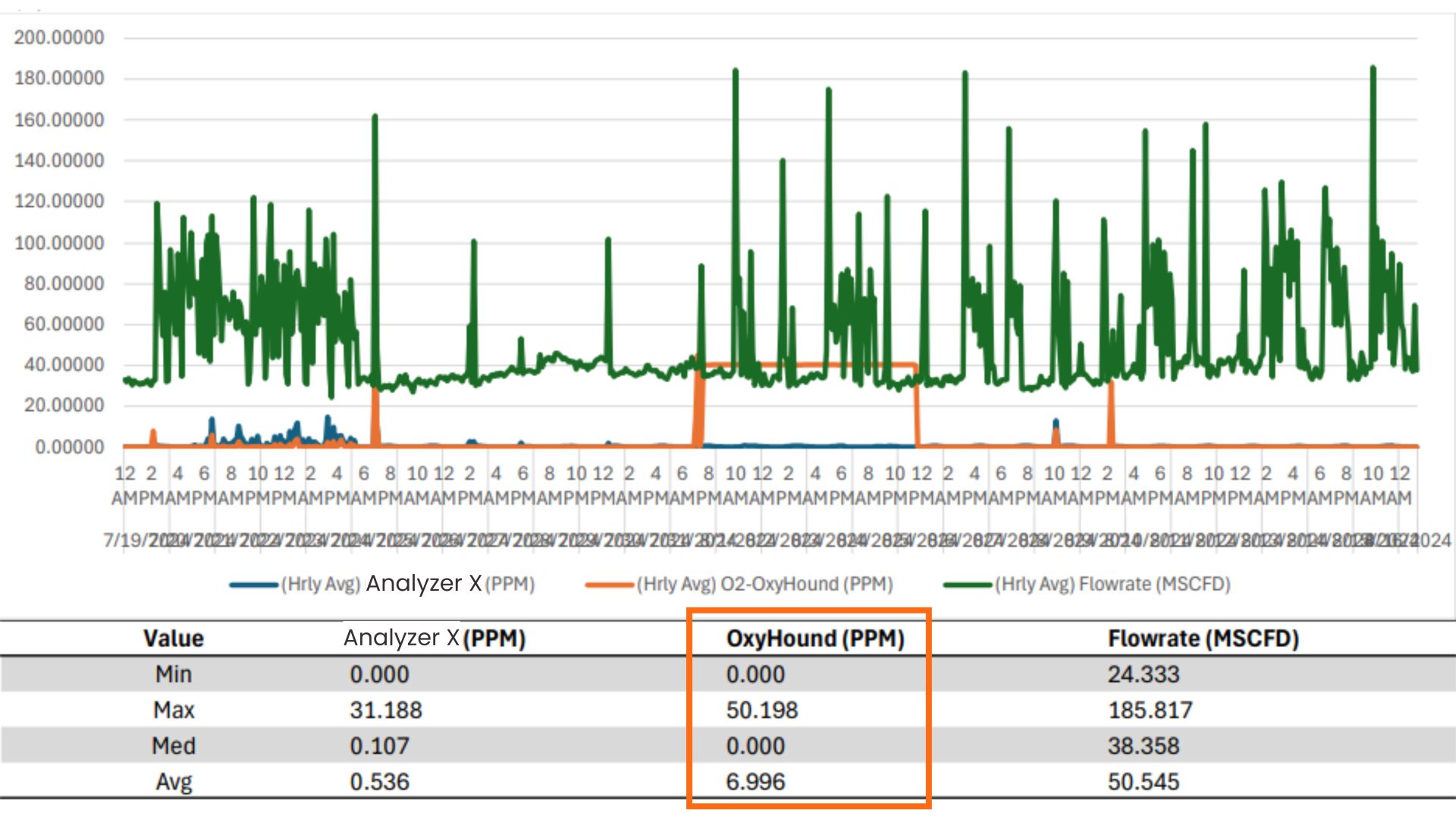

To put the OxyHound to the test, KECO and the VRU company conducted a 35-day trial at an upstream site. Both the OxyHound and a conventional electrochemical analyzer were set up to measure oxygen levels in the gas stream.

Data from both analyzers were integrated into the VRU company’s SCADA system, which sampled readings every two minutes. This data was then exported to a CSV file for analysis.

Throughout the trial, the VRU team conducted periodic validations of both analyzers, while KECO monitored the OxyHound readings remotely and reviewed the exported data. The results were clear: the OxyHound not only matched but often outperformed the electrochemical analyzer in terms of accuracy and reliability.

Maximize Operational Efficiency with Long-Term Cost Analysis

A key consideration in the evaluation was the long-term cost of ownership. Electrochemical analyzers rely on cells that react with oxygen to produce a current, and these cells degrade over time.

Typically, they need to be replaced at least twice a year, and more often if they come into contact with liquids. Each cell replacement costs around $200, translating to an annual expense of approximately $1,000. Over a decade, this adds up to $10,000, not including the additional maintenance costs associated with frequent calibrations.

In contrast, the OxyHound uses quench luminescence technology, which is non-consumptive and requires no regular consumables. Maintenance is minimal, with only occasional sensor recalibration needed. This not only reduces the long-term costs but also significantly lowers the operational burden on maintenance teams.

Why OxyHound Outperforms Traditional Electrochemical Oxygen Analyzers

The OxyHound’s success in the field trial is backed by its impressive features and benefits:

- Advanced Quench Luminescence Technology: Provides precise oxygen measurements without the drawbacks of consumable components.

- Insensitive to Common Contaminants: Unlike electrochemical cells, the OxyHound is not affected by gases like ammonia, carbon monoxide, or sulfur dioxide.

- User-Friendly Interface: The analyzer features a simple touchscreen interface and a robust design with a flame arrester vent, ensuring ease of use and safety.

- Versatility: Capable of measuring additional gases, such as hydrogen sulfide (H₂S) or carbon dioxide (CO₂), within the same unit.

- Easy Calibration: Calibration is straightforward, requiring only a standard O₂ calibration gas bottle.

- Remote Access: Equipped with KECO’s Cloud Connect feature, the OxyHound allows for remote monitoring and data access, offering unmatched convenience and control.

Industry Feedback: A Strong Impression

The feedback from the VRU company was overwhelmingly positive. Clint T., the Assets and Systems Manager, praised the OxyHound’s performance:

“We are grateful for the chance to evaluate the OxyHound gas detection system at our installation site. The system’s performance and features have made a strong impression on us, as has your dedication to customer service and support. We see the potential value of the OxyHound system for future use in our operations and are very much interested in exploring its possibilities down the road.”

Secure Reliable And Accurate Results When Monitoring Gas

The successful field trial of the KECO OxyHound highlights a promising future for industrial gas monitoring. By leveraging advanced quench luminescence technology, the OxyHound provides a reliable, low-maintenance, and cost-effective alternative to traditional electrochemical analyzers.

For industries looking to enhance their oxygen monitoring capabilities, the OxyHound represents a robust solution that not only meets but exceeds expectations.

As industries continue to seek ways to optimize their operations and reduce costs, OxyHound’s superior performance and efficiency make it a compelling choice. With its proven track record and strong industry endorsement, the KECO OxyHound is set to redefine the standards of oxygen measurement in the field.

Explore the cutting-edge capabilities of our oxygen gas analyzer, OxyHound, and discover how it delivers precision and reliability for your gas monitoring needs. Click here to learn more!

Request a Budgetary Quote for Your Application

Provide your project specifications, industry details, and end-use location to receive a tailored pricing estimate from our team.

Request Budgetary Price