Optimize H2S Scavenger Injection for Crude Oil Production

November 29, 2024

Key Challenges in H2S Management

Crude oil production faces complex challenges that impact profitability and operational efficiency. One significant issue is managing hydrogen sulfide (H2S) levels in crude oil.

Failure to address this effectively can lead to costly production shut-ins, regulatory non-compliance, and reduced revenue. Here’s how you can overcome these challenges.

1. Production Shut-Ins

Regulatory enforcement or safety concerns can lead to production halts. Each day of downtime results in substantial revenue losses, often amounting to millions of dollars. This directly threatens financial stability.

2. Inefficient Scavenger Injection

Inadequate optimization of H2S scavenger injection leads to overtreatment and excessive chemical use. Operators often rely on infrequent measurements, which result in inaccurate dosing. This can cause under-treatment, risking H2S breakthroughs, safety issues, and compliance violations.

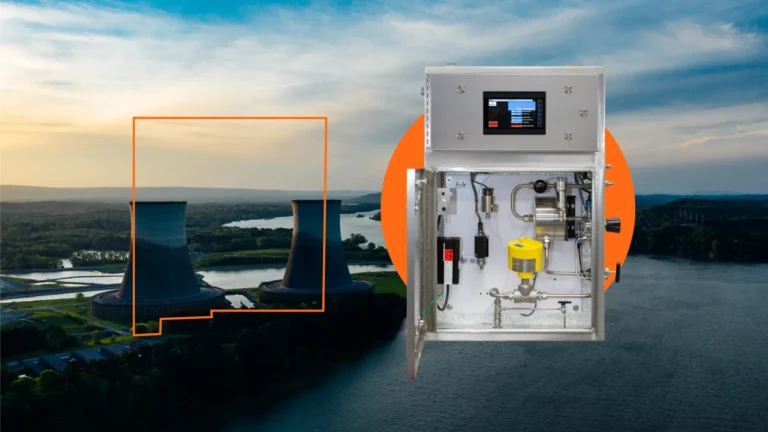

A Solution That Pays for Itself: The Model 205 PermaStream™

To avoid shut-ins and ensure operational efficiency, real-time monitoring and precise treatment are essential. The Model 205 PermaStream™ offers advanced H2S analysis technology with the following benefits:

- Real-Time, Accurate H2S Measurement: Monitors H2S in crude, water, diesel, and more.

- Exclusive Specificity to H2S: Eliminates false positives, unlike traditional methods.

- Low Maintenance: No field calibration, liquid sample conditioning, or filters required.

- Ease of Installation: Requires only one tap-point for sample entry and return.

- Proven Reliability: Conforms to ASTM methods and offers rapid response times.

Why Choose the Model 205?

Investing in the Model 205 PermaStream™ helps increase efficiency by at least 15%, preventing production shut-ins and reducing chemical costs. With its robust technology, the device ensures compliance and safety, protecting your operations from unexpected disruptions.

Additional Features:

- Measures in ppb, ppm, or percentage ranges.

- Operates in-line at process pressure and flow.

- Offers a reliable, long-term solution for H2S detection.

Boost Your Operational Efficiency Today

The Model 205 PermaStream™ is the industry’s leading solution for H2S monitoring and treatment optimization. By integrating this technology, you can:

- Prevent production losses.

- Optimize chemical use.

- Ensure regulatory compliance and safety.

Don’t let H2S disrupt your production. Learn more about how the Model 205 PermaStream™ can transform your operations today by filling out the RFQ below.

Request a Budgetary Quote for Your Application

Provide your project specifications, industry details, and end-use location to receive a tailored pricing estimate from our team.

Request Budgetary Price