Optimization Of Oil Field Operations

KECO’s Precision Tools For Safer Oil Field Performance

KECO provides advanced analyzers for detecting hazardous gases and liquids in upstream oil operations. Each is tailored for specific applications, including crude oil, gas, and water analysis. The analyzers below address critical upstream challenges:

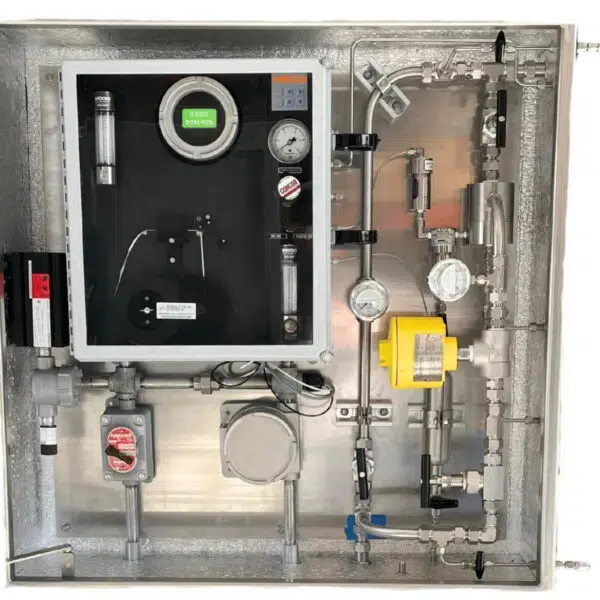

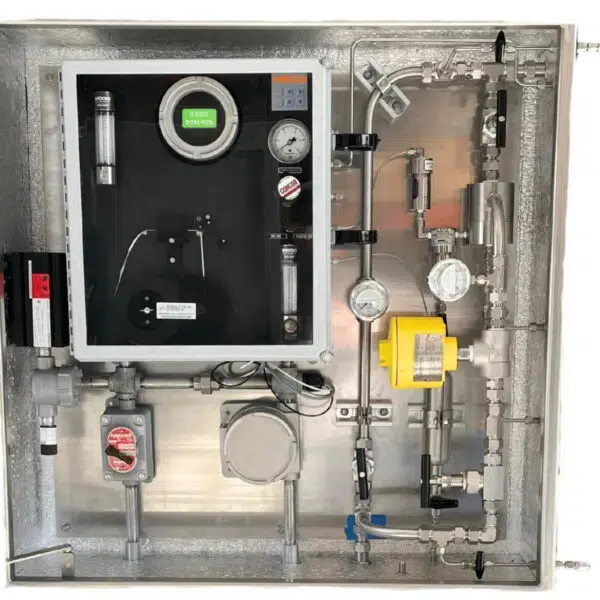

H2S in Crude Oil Analyzer

KECO’s 205 PermaStream continuously measures H₂S in light-to-heavy crude via patented Sample Transfer Stripper (STS) membrane technology, supplying a dry, interference-free gas sample to a rateometric-colorimetric detector. With no field calibration and minimal maintenance, it safeguards assets, optimizes production, and meets regulatory limits.

Learn More About H2S in Crude Oil AnalyzerH2S in Gas Analyzer (Electrochemical)

The KECO H2S in Gas Analyzer (Electrochemical) provides continuous, real-time monitoring of hydrogen sulfide in oil field natural gas streams, helping ensure personnel safety, prevent corrosion, and maintain gas quality for processing and pipeline delivery. Its regulated flow system and microprocessor-controlled electrochemical sensor deliver accurate readings on a durable, H2S resistant platform with an intuitive touchscreen for operational control in demanding field conditions.

Learn More About H2S in Gas Analyzer (Electrochemical)

CO2 Process Analyzer

The KECO CarbonHound CO2 Process Analyzer provides continuous, real-time monitoring of carbon dioxide in oil field gas streams using non-dispersive infrared technology. With a regulated sample flow and microprocessor-controlled detection, it delivers accurate data essential for process control, corrosion management, and enhanced oil recovery. The analyzer features a touchscreen interface displaying real-time and historical readings, alarms, and diagnostics. Built with corrosion-resistant materials, it ensures reliable, low-maintenance operation in harsh oil field environments.

Learn More About CO2 Process AnalyzerH2S in Liquids Process Analyzer

The KECO 205 PermaStream H2S in Liquids Analyzer provides accurate, continuous measurement of hydrogen sulfide dissolved in crude oil, condensate, water, and other liquids using the patented Sample Transfer Stripper (STS) and membrane technology. The STS efficiently separates H2S from the liquid phase without the need for complex headspace columns, delivering a clean, dry gas sample to a chemically specific ratiometric-colorimetric detector. This low-maintenance, field-calibration-free analyzer enhances safety, corrosion prevention, and regulatory compliance in oil field operations by reliably detecting H2S at ppb to percent levels.

Learn More About H2S in Liquids Process Analyzer

Portable H2S Analyzer

The KECO Series 150 Portable H2S Analyzer provides accurate, continuous hydrogen sulfide measurement in oil field environments, supporting critical safety checks, leak detection, and confined space monitoring. Its compact, lightweight design with rechargeable battery and interference-free lead acetate tape technology allows reliable field use for detecting H2S concentrations from ppb to 500 ppm. With real-time data display, low maintenance, and optional data logging, it ensures fast, precise monitoring to protect personnel and equipment across multiple oil field locations.

Learn More About Portable H2S AnalyzerVOC / Hydrocarbons in Water Analyzer

The 204 PermaStream VOC / Hydrocarbon in Water Analyzer measures total hydrocarbons and VOCs in water using KECO’s membrane-based stripping technology to eliminate false positives common in UV fluorescence methods. Designed for continuous online analysis, it separates hydrocarbons from the water sample using heat and Henry’s Law, then delivers them to a metal-oxide sensor for accurate detection. Ideal for oil field produced water monitoring, it ensures reliable, real-time data with advanced HMI controls, remote access, and multiple communication outputs, supporting environmental compliance and effective water management in oil field operations.

Learn More About VOC / Hydrocarbons in Water Analyzer

Why Oil Field Operators Trust KECO Analyzers

KECO analyzers are essential to oil field operations, providing accurate detection of critical gases like H2S, CO2, and O2. They enable effective process control, safeguard equipment, and support compliance with industry standards.

Benefits That Make A Measurable Difference

- Accurate, interference-free gas detection across ppb–percent ranges

- Calibration-free, low-maintenance operation that lowers OPEX

- Rugged construction for reliable performance in corrosive, high-temperature environments

- Real-time digital outputs that speed decisions and minimize unplanned downtime

- ASTM-compliant measurements to meet regulatory and contractual requirements

Breakthrough Technology Behind Every KECO Analyzer

KECO analyzers apply advanced membrane technology to separate and extract target compounds like H2S and VOCs from liquid and gas streams in oil field operations. This method ensures a clean, interference-free sample for accurate detection without the complexity of traditional systems. Detection is carried out using specialized techniques such as lead acetate tape for sulfur, electrochemical sensors for H2S, and NDIR for CO2. Paired with intuitive digital interfaces and remote access options, these technologies deliver reliable, real-time data crucial for safe and efficient oil field performance.

Detect Critical Gases with KECO Analyzers

Deploy field-proven instruments for real-time H₂S, CO₂, O₂, and VOC monitoring. Request a quote to enhance safety, efficiency, and compliance.