Smarter Control With:

Human Machine Interface (HMI) Technology

Smarter Control With:

Human Machine Interface (HMI) Technology

In today’s industrial landscape, precision and ease of use are essential. KECO’s Human Machine Interface (HMI) technology gives operators real-time control, remote monitoring capabilities, and an intuitive user experience that simplifies complex processes. From improved visibility to enhanced safety, our HMI solutions are changing how gas analyzers are managed across various industries.

Streamlined Gas Analysis Through HMI Innovation

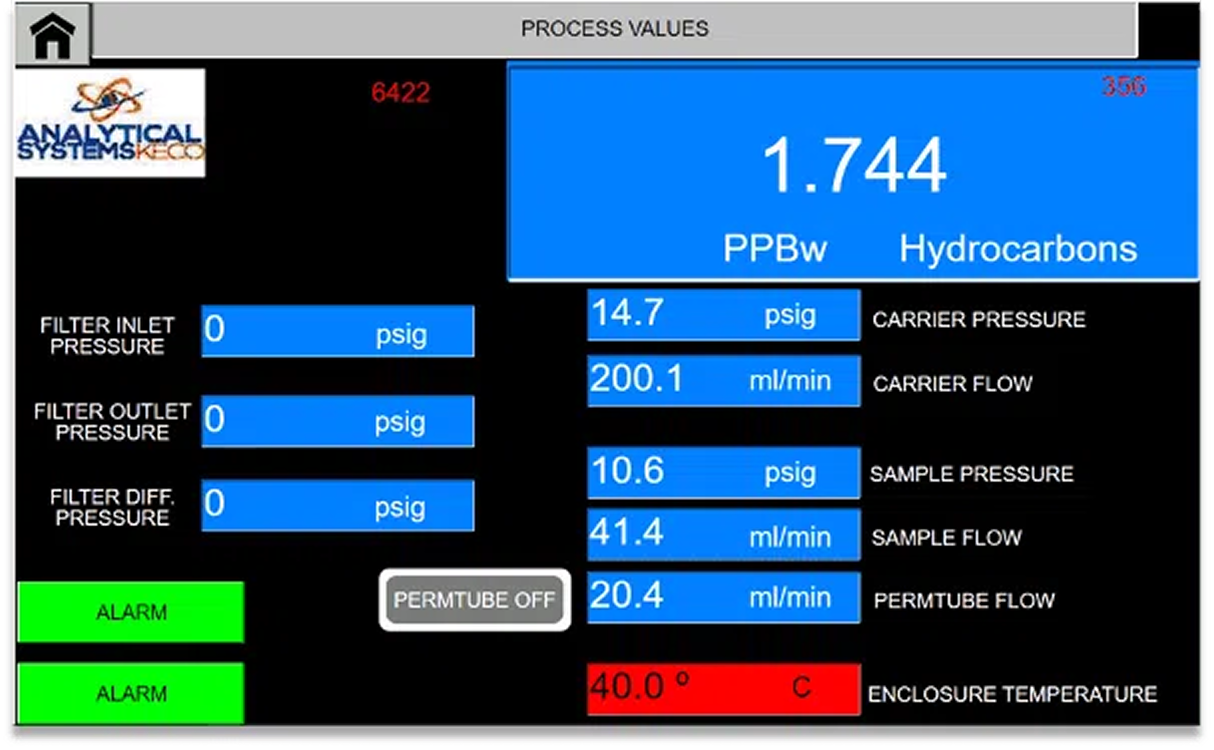

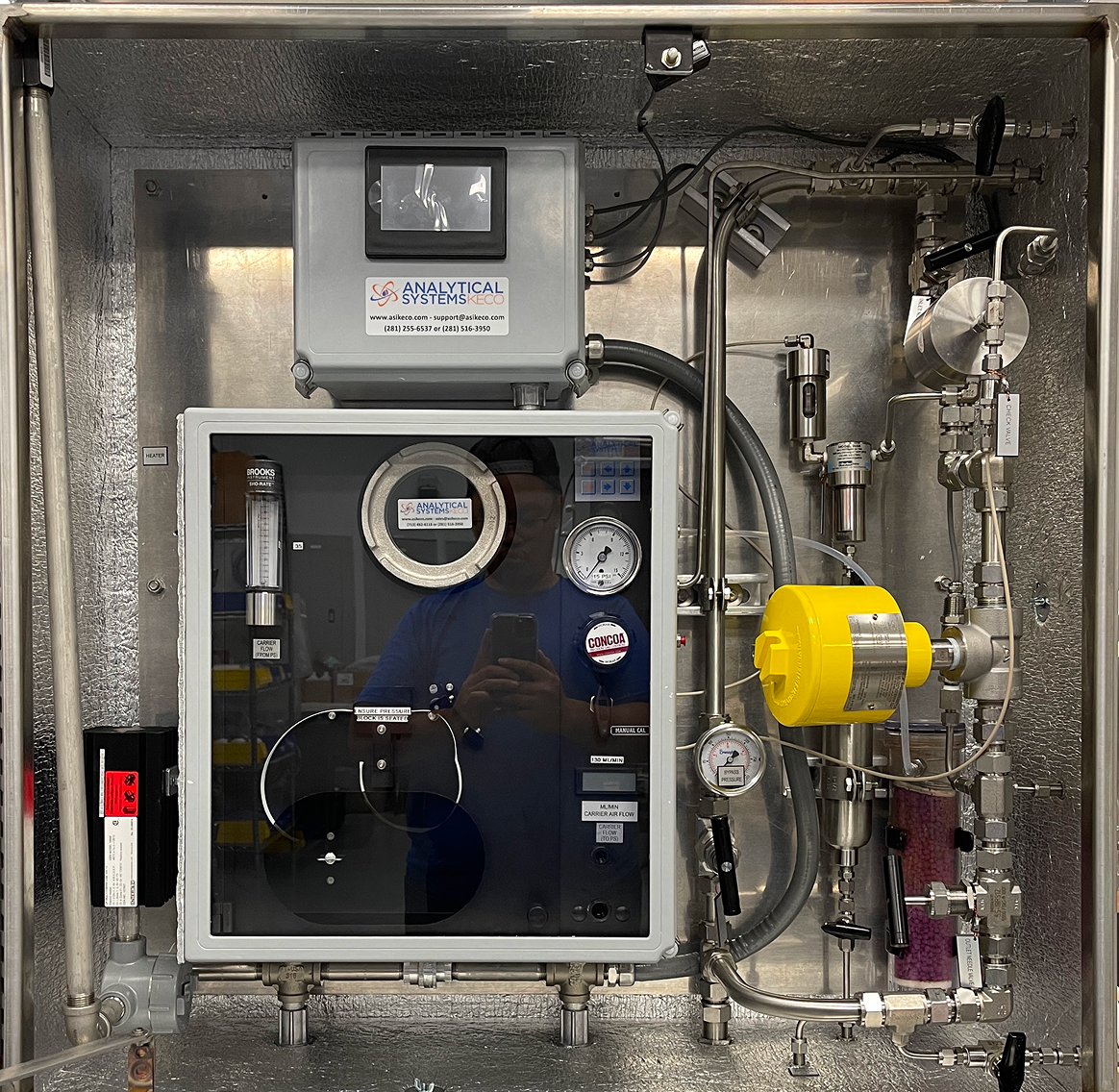

KECO’s HMI simplifies gas analysis with a large, full-color touchscreen for easy calibration, diagnostics, alarms, and data logging. Operators get fast access to clear visuals and streamlined workflows—on-site or remotely.

Key Features of HMI

Interface

User-Friendly Touchscreen Design

KECO’s HMI features a spacious, high-resolution display that provides easy access to real-time data, historical trends, and system controls. Logical menu structures and intuitive navigation reduce training time and eliminate confusion, ideal for both experienced technicians and new operators.

Seamless Remote Monitoring

Through cellular or satellite connectivity, KECO’s HMI communicates directly with cloud servers, enabling remote users to log in securely through KECO Connect. Operators and maintenance teams can access current readings, alarm history, and system diagnostics in real time. This is particularly beneficial for remote installations such as offshore platforms or unmanned stations, where physical access is limited.

Seamless Remote Integration

KECO Connect is a secure online platform that mirrors the HMI experience, giving users remote access to system readings, settings, and diagnostics. It allows configuration of setpoints, triggering of calibrations, and downloading of logged data. Users can receive real-time alerts, adjust parameters, and log data, all without leaving their desk. The platform ensures prompt detection of issues such as analyzer drift, gas cell fouling, or sensor degradation.

Advantages Of Our HMI Technology

Applications of

HMI Technology

Across Different Industries

Gas: Environmental Monitoring And Emission Detection

Deployed in fenceline monitoring, landfill gas detection, and VOC compliance systems, KECO analyzers with HMI allow facilities to log emission levels continuously, generate compliance reports, and respond to exceedances without delay.

Oil: Industrial Process Control And Optimization

In chemical processing, refining, and petrochemical production, KECO’s HMI interfaces help monitor key variables like H2S, CO2, or methane. The HMI simplifies process turning and quality control while ensuring compatibility with automation frameworks.

KECO Analyzers

With HMI Technology

Dual H2S & CO2 Gas Analyzer

VOC / Hydrocarbons in Water Analyzer

H2S in Gas Analyzer

Methane Analyzer

Oxygen Analyzer

CO2 Process Analyzer

How KECO

Supports HMI Users

At KECO, we go beyond delivering high-performance analyzer interfaces, we provide end-to-end support to help clients fully leverage our advanced HMI technology. From system customization to integration assistance and ongoing technical service, we ensure that your team operates with confidence, efficiency, and total control.

KECO Connect Monitoring Platform

Centralizes real-time data from multiple analyzers in a single dashboard. Offers remote analytics, alarm tracking, and user permission management.

Software Updates & Integration Support

KECO provides periodic firmware updates and integration assistance with third-party software platforms. Support includes Modbus registers, analog scaling, and network protocols.

Customization & Setup Assistance

Tailored configurations are available for units requiring unique alarm schemes, display formats, or protocol mapping. KECO offers remote setup support, commissioning guidances, and on-site integration services.

Elevate Your Efficiency With KECO’s Advanced HMI Technology

KECO’s HMI technology is redefining the way operators interact with gas analyzers across a wide range of industries. Whether you’re managing environmental compliance, optimizing industrial processes, or overseeing remote installations, our advanced HMI solutions provide intuitive control, real-time data access, and seamless integration with plant systems. From improving operational visibility to minimizing downtime and enhancing safety, KECO’s HMI empowers users to work smarter, faster, and with greater confidence.

Discover how KECO’s touchscreen and remote-access HMI technology can elevate your analyzer performance, streamline monitoring, and support more efficient, compliant operations.

Learn More About KECO’s HMI Solutions

Explore these technical resources for more insight:

By integrating KECO’s advanced HMI technology into your operations, you can enhance analyzer performance, improve safety, and maintain full visibility across your process, from anywhere.