Refining Hydrogen Sulfide Detection in Crude Oil

KECO Analyzers Designed For Crude Oil H2S Analysis

We deliver trusted H₂S detection technologies that improve measurement precision, operational reliability, and regulatory alignment in crude oil analysis. Here are the analyzers for this use:

Laboratory H2s In Crude Oil Analyzer

The 205L is a compact, high-precision analyzer built for fast, interference-free measurement of hydrogen sulfide (H₂S) in crude oil and similar liquids. It offers a simple, one-button operation with results in just minutes, making it ideal for field use, quality control, and compliance monitoring.

H2s In Crude Oil Analyzer

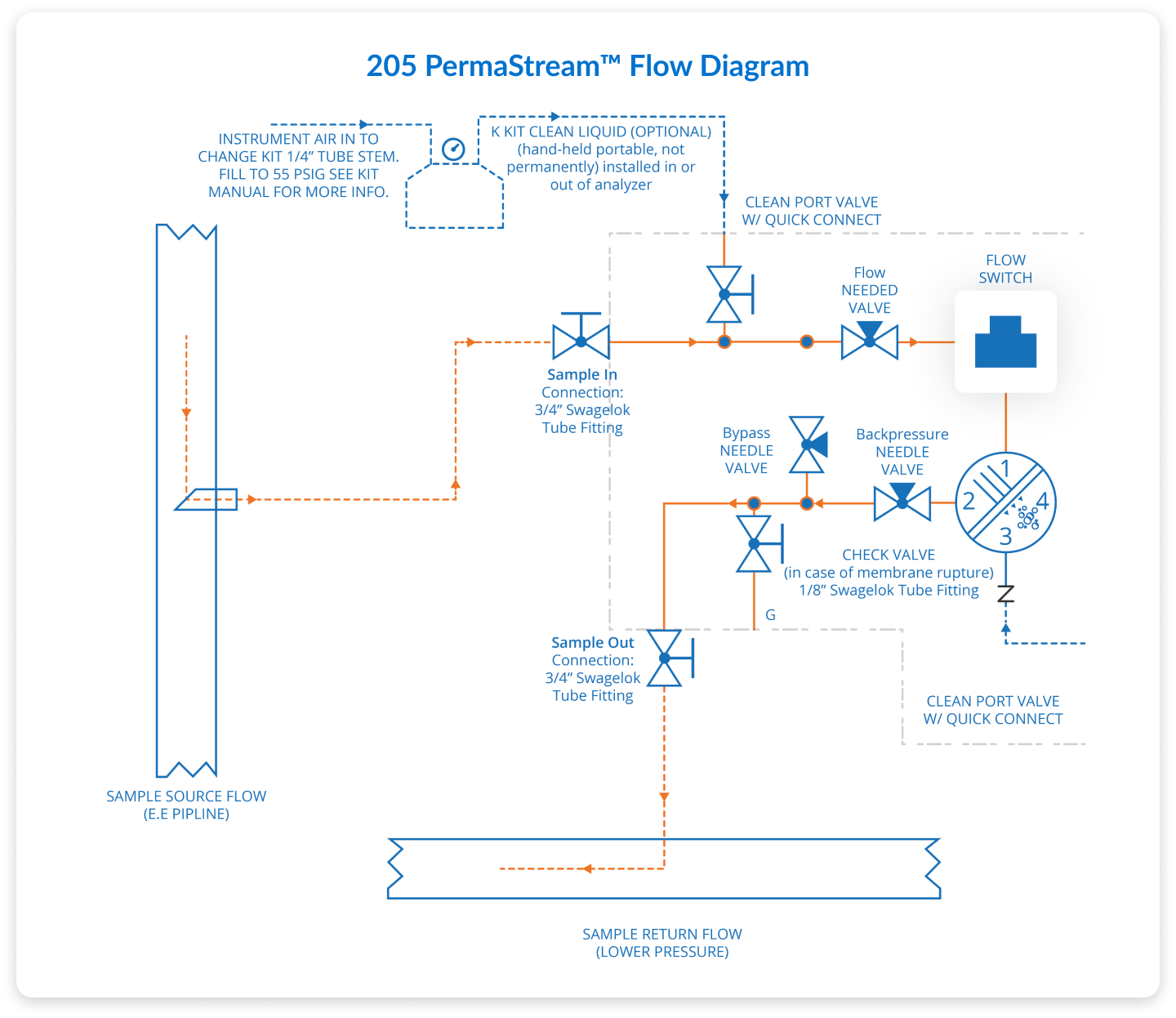

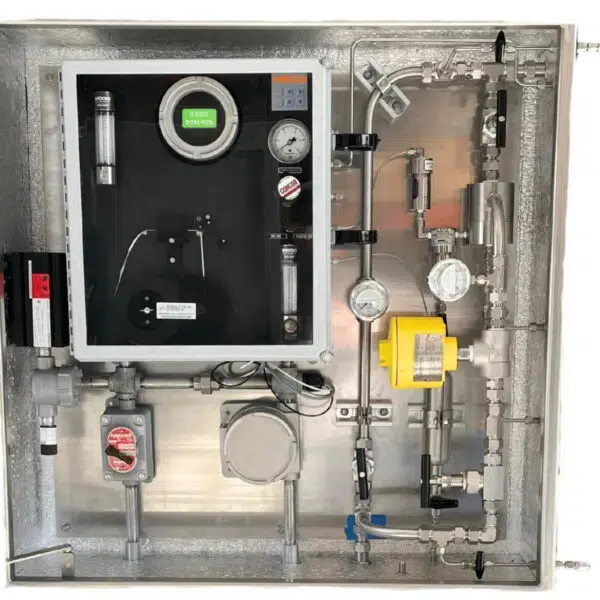

The 205 PermaStream is a robust process analyzer for continuous and highly accurate hydrogen sulfide (H₂S) measurement in crude oil. Designed to handle light to heavy crude, it delivers real-time data without the need for routine calibration or sample conditioning, making it ideal for demanding environments.

How KECO Enhances Accuracy and Process Integrity

In crude oil analysis, dependable H₂S monitoring tools are essential for ensuring operational stability, protecting personnel, and meeting industry demands. KECO systems offer real-time insight to detect unwanted gases, manage treatment steps, and maintain processing efficiency. By enabling swift, data-driven action, they help avoid failures, improve output, and strengthen control across upstream and downstream sectors.

Benefits Of Consistent H₂s Measurement

- Improve product quality and process consistency

- Eliminate cross-interference and false positives

- Automate monitoring to reduce manual testing

- Remove hazards of open-air H₂S testing

- Maintain accuracy under changing process conditions

- Enable real-time remote visibility into H₂S levels

Advanced Systems For H₂s Detection

KECO analyzers combine membrane-based gas extraction with robust sensor options, including colorimetric tape and electrochemical cells, to deliver real-time, accurate H₂S readings across a wide concentration range. The PermaStream Membrane enables gas-phase analysis without dilution, conditioning, or complex sample prep.

Designed for challenging environments, KECO systems feature intuitive interfaces, continuous digital outputs, and optional remote monitoring for seamless integration into crude oil and hydrocarbon process streams.

Detect H2s In Crude Oil With Confidence And Precision

Ensure regulatory compliance, reduce risk, and maintain product integrity with KECO’s proven H₂S detection technology. Start optimizing your crude oil monitoring system today.