KECO Sensor Technologies:

Advancing Precision Detection

KECO Sensor Technologies:

Advancing Precision Detection

Accurate monitoring is essential for industrial safety, compliance, and efficiency. KECO’s sensor technologies are built to perform in harsh environments, detect trace-level compounds, and operate with minimal maintenance. Designed for demanding applications, they deliver reliable data that supports real-time decision-making and optimized operations.

Advanced Sensing Methodologies Deployed in

KECO Systems

High-Performance KECO Proven Sensor Technologies

Key Features of KECO’s

Industrial-Grade Sensor Solutions

High Performance and Accuracy

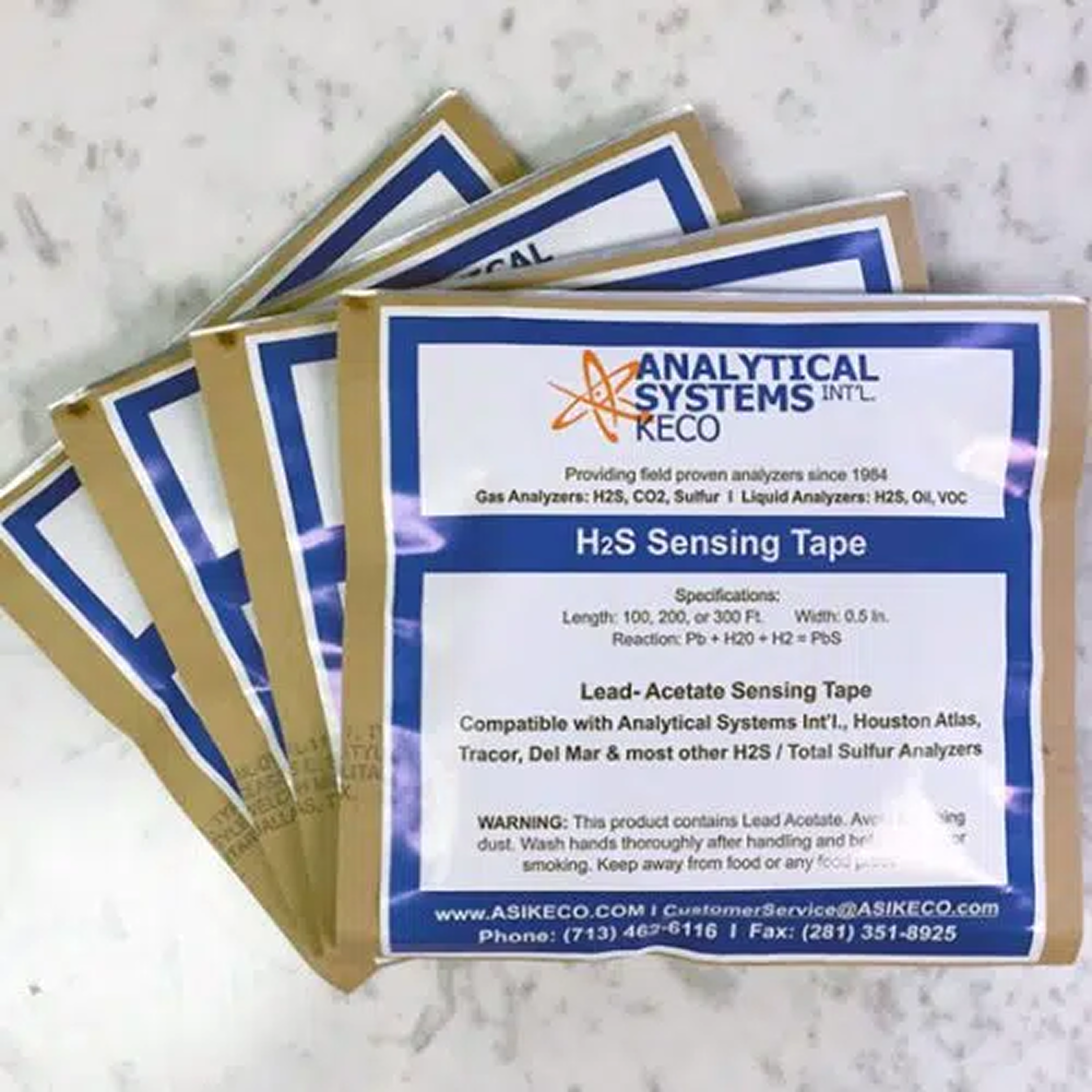

KECO analyzers use advanced detection methods such as lead-acetate tape and optical quench luminescence to deliver high-sensitivity, target-specific measurements with minimal cross-interference—even in complex sample matrices. Real-time output supports immediate operational adjustments and data-driven control.

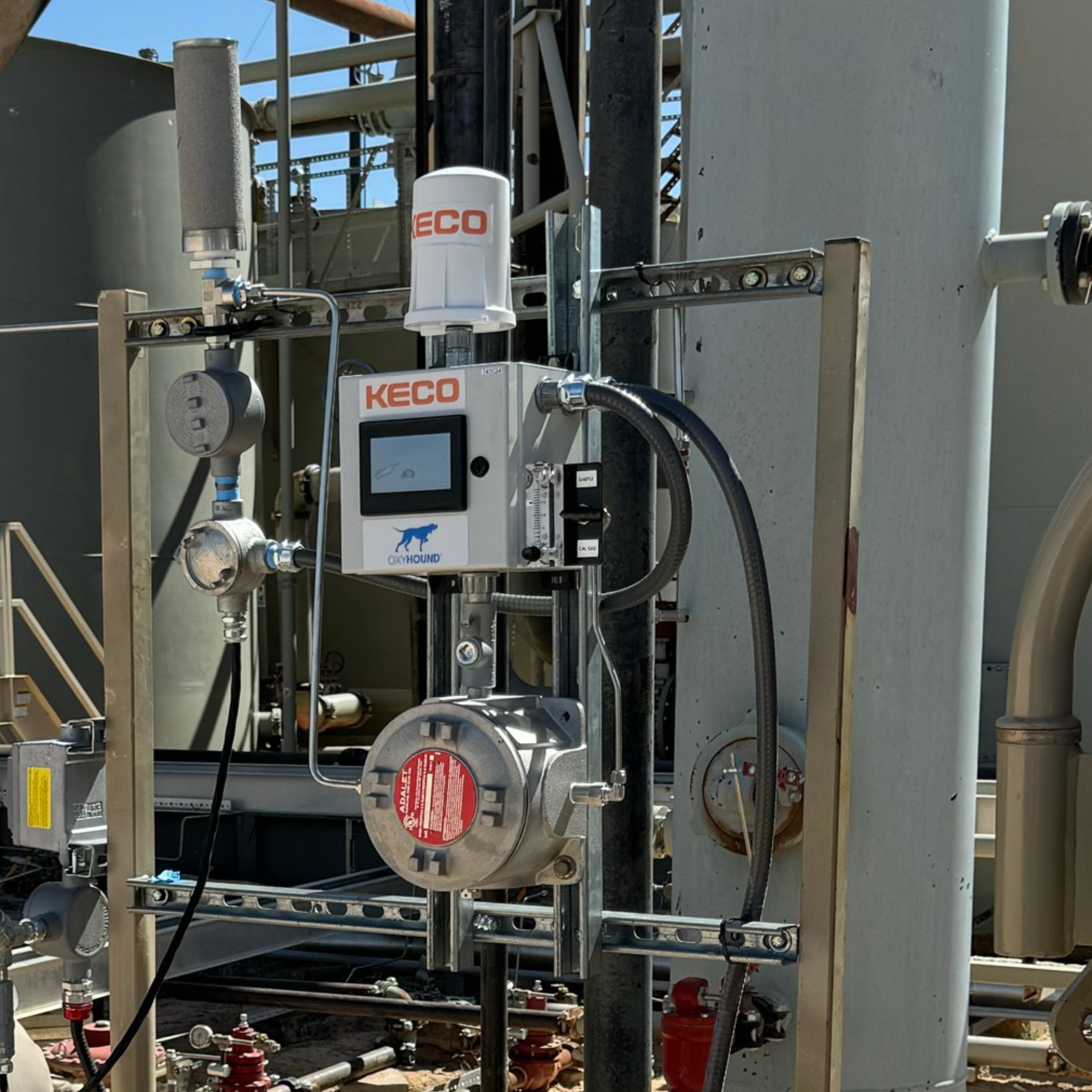

Industrial-Grade Reliability

Built for harsh environments, KECO systems withstand corrosive exposure, pressure fluctuations, and temperature extremes. Rugged hardware reduces calibration needs and moving parts, minimizing maintenance and maximizing uptime across demanding applications.

Flexible, Compliance-Ready Integration

Configurable for diverse sectors including refining, chemical processing, wastewater, and power generation, each system supports tailored communication protocols and installation setups. All solutions align with EPA, OSHA, and international standards for measurement integrity and reporting.

Benefits of KECO's Proven Sensor Technology

Applications Across Different Industries

Precision Monitoring for Oil & Gas Operations

KECO technologies support gas composition analysis, process optimization, and leak detection to ensure product quality, maximize efficiency, and minimize safety and environmental risks in upstream and downstream operations.

Process Safety and Emissions Control in Petrochemical Production

Real-time monitoring of reactors, corrosive gas detection, and emissions tracking enable chemical producers to maintain process stability, protect assets, and meet regulatory obligations with confidence.

Reliable Detection for Wastewater Treatment Facilities

Continuous VOC and H₂S monitoring helps safeguard infrastructure, while accurate data improves process control and simplifies environmental reporting for treatment facilities.

Combustion and Emissions Analysis in Power Generation

From boiler feedwater quality to emissions and combustion gas analysis, KECO systems help power plants maintain operational integrity, optimize fuel efficiency, and comply with environmental standards.

Gas and Air Quality Solutions for Industrial Manufacturing

Gas monitoring solutions ensure consistent product quality and safe working environments, with customizable sensor integration to meet the specific demands of varied manufacturing operations.

Air Quality and Emissions Oversight for Environmental Compliance

KECO analyzers enable precise air sampling, stack emissions analysis, and remote environmental assessments to support pollution control strategies and regulatory compliance.

Gas Monitoring and Quality Control in Food & Beverage Production

Accurate CO₂ monitoring, moisture detection, and gas purity verification ensure safety, consistency, and extended shelf life in beverage carbonation and food processing environments.

KECO Measurement Solutions

That Drive Results

VOC Analyzer

Oxygen Analyzer

H2S in Gas Analyzer

CO2 Process Analyzer

How KECO

Supports Users With Sensor Technologies

Getting value from measurement technology isn’t just about the hardware, it’s about how well it fits into your workflow, how quickly your team can master it, and how easily it scales over time. That’s why our support model focuses on flexibility, training, and technical partnership at every stage.

Comprehensive Product Training

Practical, hands-on instruction ensures your team is equipped to operate and maintain systems confidently from day one.

24/7 Technical Support

Direct access to application specialists and engineers, ready to assist with configuration, troubleshooting, or system tuning whenever needed.

Customized Solutions

Sensor configurations are tailored around your process requirements, with close collaboration to align performance, integration, and compliance needs.

Ongoing System Optimization

Post-deployment reviews help maintain accuracy and system health, adapting to changes in process conditions or regulatory demands.

Maintenance And Calibration Services

Proactive service programs extend equipment life, improve reliability, and help avoid unplanned interruptions.

Easy Integration With Existing Systems

Designed to work with common control platforms and protocols, simplifying setup and reducing engineering overhead.

Continuous Product Development

Ongoing investment in R&D ensures technologies remain on the leading edge, keeping pace with evolving industry standards and process demands.

Maximize Performance with KECO’s Advanced Detection Systems

KECO’s proven sensor technologies set the standard for precision monitoring in the most demanding industrial environments. From trace-level gas detection to continuous liquid analysis, our sensor systems deliver dependable performance, real-time insight, and long-term value.

Explore how KECO’s advanced sensing solutions, built on decades of field-proven expertise, can optimize your operations, strengthen compliance, and elevate process reliability.

Learn More About KECO’s Sensor Technologies

For additional insights into KECO’s Sensor Technologies, check out these resources:

Explore how KECO’s innovative sensor solutions are making a difference across industries. Our blog posts and case studies provide real-world insights into the performance, reliability, and impact of our analyzers.