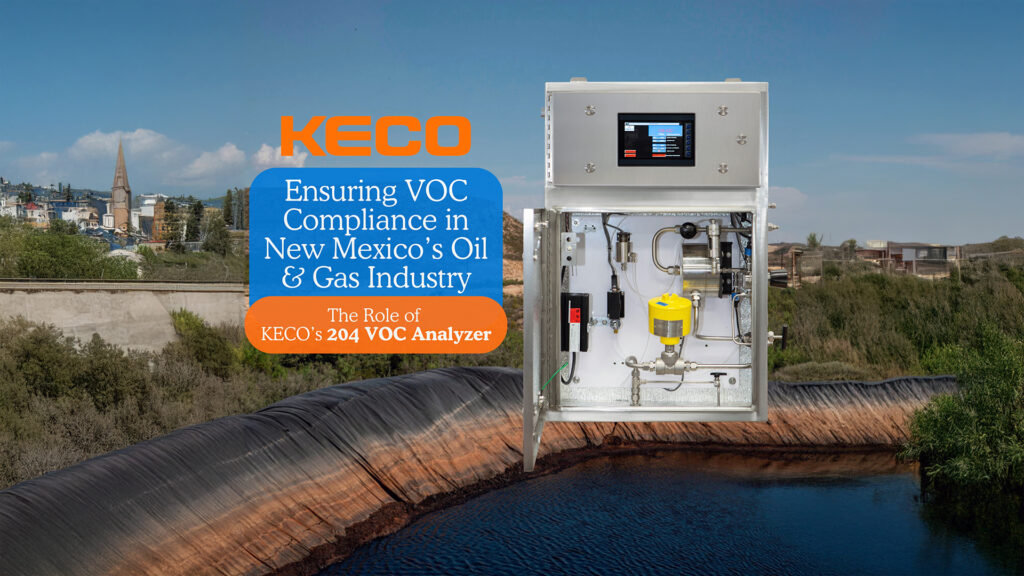

Achieve VOC Compliance in New Mexico With The KECO Model 204

November 5, 2024

In the oil and gas industry, volatile organic compounds (VOCs) pose significant environmental and compliance challenges, especially under New Mexico’s new regulations.

For facilities operating in high-ozone zones, these rules aren’t just a guideline—they’re mandatory.

This guide unpacks the critical aspects of CEMS for VOC monitoring under New Mexico’s Produced Water Act and Ozone Precursor Pollutants Rule, and introduces a powerful tool for maintaining compliance: the KECO Model 204 VOC Analyzer.

Compliance at a Glance: Continuous Monitoring Protocol

To meet VOC emission requirements effectively, the KECO Model 204 (CEMS) offers a streamlined approach:

- Detection: Identifies abnormal VOC concentrations in real time as a Continuous Emissions Monitoring System.

- Validation: Takes a manual sample to confirm the elevated VOC levels.

- Correction: Allows quick corrective action, preventing the levels from surpassing regulatory limits and helping facilities avoid fines.

By integrating these steps, operators can address VOC issues immediately, ensuring compliance while keeping operations running smoothly.

Why CEMS VOC Emission Monitoring Is Critical In The Oil & Gas Sector

New Mexico’s regulatory landscape has tightened significantly, particularly around VOC emissions due to their impact on ozone levels and public health.

Under the Ozone Precursor Pollutants Rule (NMAC 20.2.50), the state classifies facilities based on their Potential to Emit (PTE)—a measure of the highest pollutant level a facility could emit without controls in place.

Facilities are then assigned monitoring and inspection frequencies:

- PTE under 2 tons/year: Annual VOC emissions inspection.

- PTE between 2 and 5 tons/year: Semi-annual inspections.

- PTE over 5 tons/year: Quarterly VOC monitoring and inspections.

These guidelines directly impact facilities in high-ozone areas like the Permian Basin, where real-time compliance is essential to avoid fines and ensure public safety.

Real-Time Emission Using The KECO Model 204 Analyzer

Traditional VOC monitoring methods, like surface air sampling near water ponds, can yield inaccurate data due to environmental factors such as wind and temperature shifts. The KECO Model 204 VOC Analyzer is a CEMS that offers a precise alternative by capturing VOC data directly at the source, minimizing environmental influence.

Key Benefits Of The KECO Model 204 Analyzer

- Continuous, Source-Based Measurements: Real-time VOC data is captured directly at emission points, ensuring that readings are accurate and unaffected by surrounding conditions.

- Immediate Alerts: Built-in alarm systems notify operators as soon as VOC concentrations approach unsafe levels, enabling fast corrective action.

- Streamlined Operations: By reducing reliance on manual sampling, the Model 204 improves operational efficiency, allowing staff to focus on productivity.

- Enhanced Reporting Accuracy: Continuous data aligns with state and federal regulations, including the stringent standards of the New Mexico Produced Water Act.

Efficient Emission Management By The KECO Model 204

The Model 204 goes beyond compliance with its Continuous Monitoring Protocol, designed to detect, validate, and correct VOC levels before they reach regulatory limits:

- Detection: The system continuously scans for any abnormal rise in VOC concentration.

- Validation: Once a spike is detected, a manual sample is taken to confirm accuracy.

- Correction: If confirmed, corrective actions are implemented immediately, preventing exceedance of regulatory thresholds and helping the facility avoid fines.

This proactive monitoring strategy ensures that facilities can address emissions efficiently, keeping them well within PTE guidelines and reducing the frequency of regulatory interventions.

Achieve Compliance With Advanced Monitoring Solutions

Staying compliant with New Mexico’s VOC emissions standards requires precise and continuous monitoring. KECO’s VOC analyzers are purpose-built for this challenge, offering a dependable solution for real-time emissions tracking.

By adopting this technology, oil and gas operators can enhance their operational efficiency, prevent fines, and demonstrate their commitment to environmental responsibility.

Next Steps: For more details on how the KECO Model 204 can support your facility’s VOC compliance, complete the RFQ form below to explore tailored solutions.

Request a Budgetary Quote for Your Application

Provide your project specifications, industry details, and end-use location to receive a tailored pricing estimate from our team.

Request Budgetary Price