4 Critical Things You Need to Know When Using Online H2S Analyzers

October 7, 2015

If you operate an H2S analyzer, there are 4 things you must know for successful measurements. If you haven’t considered the 4 steps listed below, it’s likely your gas H2S analyzer is not operating as accurately or as reliable as it could.

1.) Check the Material of the Wetted Parts

It’s far too often manufactures of H2S analyzers use wetted parts in their analyzers that readily absorb H2S. When H2S is absorbed into parts materials, a phenomenon called “in-gassing” will occur. In-gassing results when H2S is absorbed in materials before it reaches the detector. This results in lower H2S readings than what is actually in the sample.

Ensure the wetted part materials is inert such as 316L stainless steel or PTFE (Teflon). Stay away from materials such as brass, carbon steel or nickle.

2.) Be Aware of False High Readings

You could be experiencing a product shut-in even though your H2S levels are in check and not over your limit. These false high readings or “false positives” are very common in the analyzer industry. False positives occur when the H2S analyzer measures components that “look” similar to H2S but are not actually H2S.

The most common types of interference is ethyl-mercaptan and methyl-mercaptan.

You may be saying to yourself “we don’t inject mercaptans in our gas so we are fine.”

However, what many people fail to realize is that mercaptans is naturally occurring in the ground. You may not be aware of the presence of mercaptans in your sample.

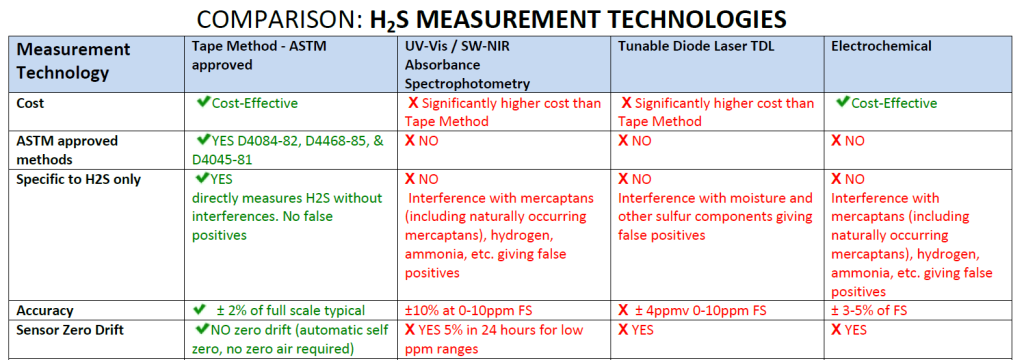

The chart below shows which type of H2S analyzer methods suffer from cross-sensitive to components other than H2S.

ASI Keco offers the H2S tape method analyzer that never suffers from cross-interference.

3.) Process Analyzers Are Only as Good as the Sampling System

It’s easy to focus so much of your time and attention on your analyzer you forget how important the sampling system is. If the sampling system is not set up properly, you analyzer will not perform. Verify the wetted part materials (see step 1). Also ensure there are no free liquids getting through the sample lines. H2S is readily absorbed in liquids.

We would be happy to design a sampling system for your analyzer. Just give us a call!

4.) Ensure the Vent Lines Out of the Analyzer are Clear

Back pressure on the analyzer’s vent lines can lead to false high readings. Dirt, debris and bugs can cause back pressure on the vent line. When bugs such as dirt dobbers smell hydrogen sulfide, they think its lunch. When they craw into the sample vent line they die quickly, but this causes back pressure. Be sure to install “bug guard” screens at the end of the analyzer vent to prevent this from happening.

—————————————————

Request a Budgetary Quote for Your Application

Provide your project specifications, industry details, and end-use location to receive a tailored pricing estimate from our team.

Request Budgetary Price