Real-time analyzers for process & quality control

Protect your people, profits and the environment by using KECO’s proven liquid and gas analyzers.

Real-time analyzers for process & quality control

Protect your people, profits and the environment by using KECO’s proven liquid and gas analyzers.

KECO Is Trusted By

Measurements

Industries Served

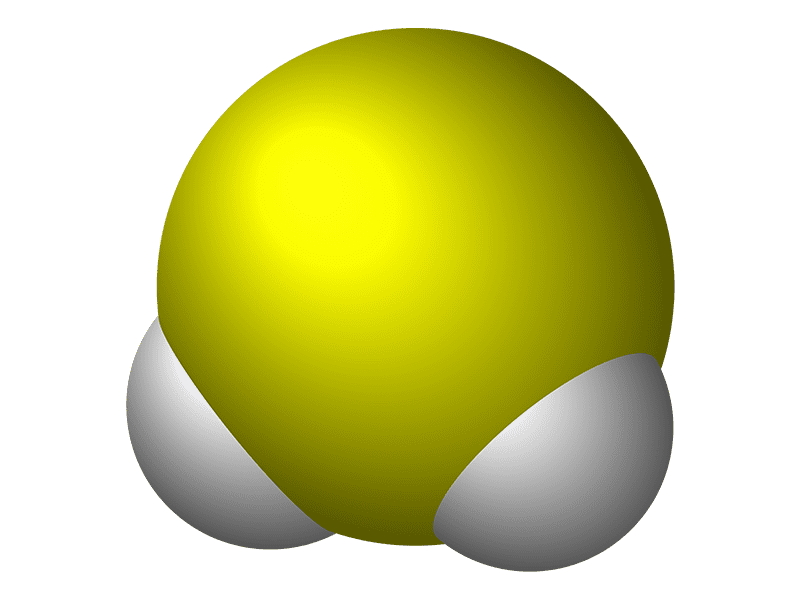

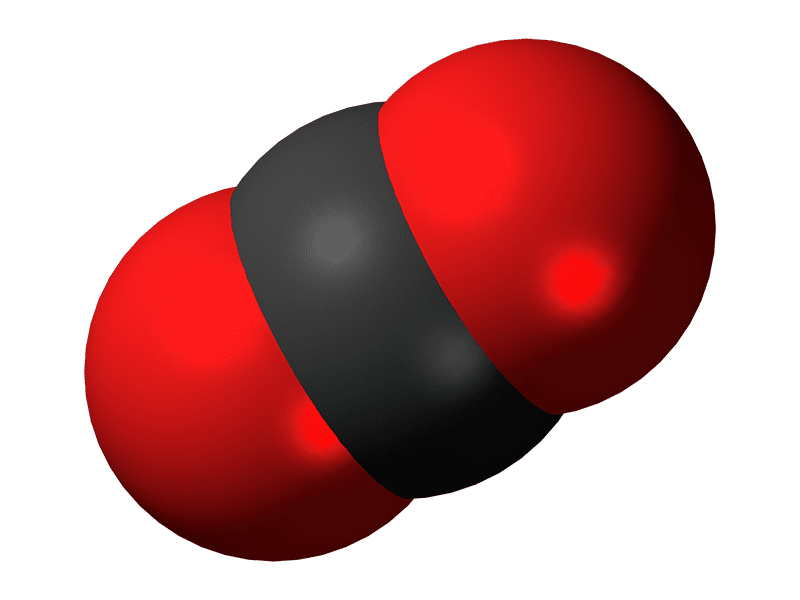

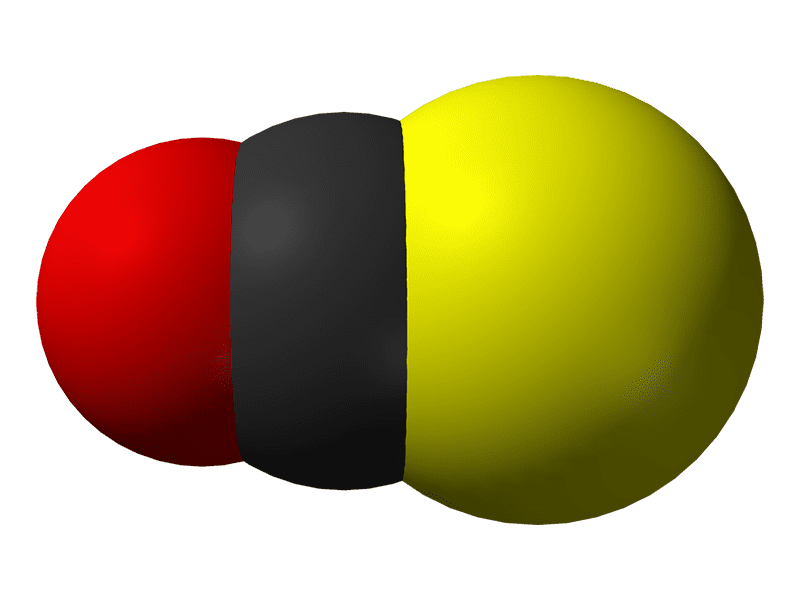

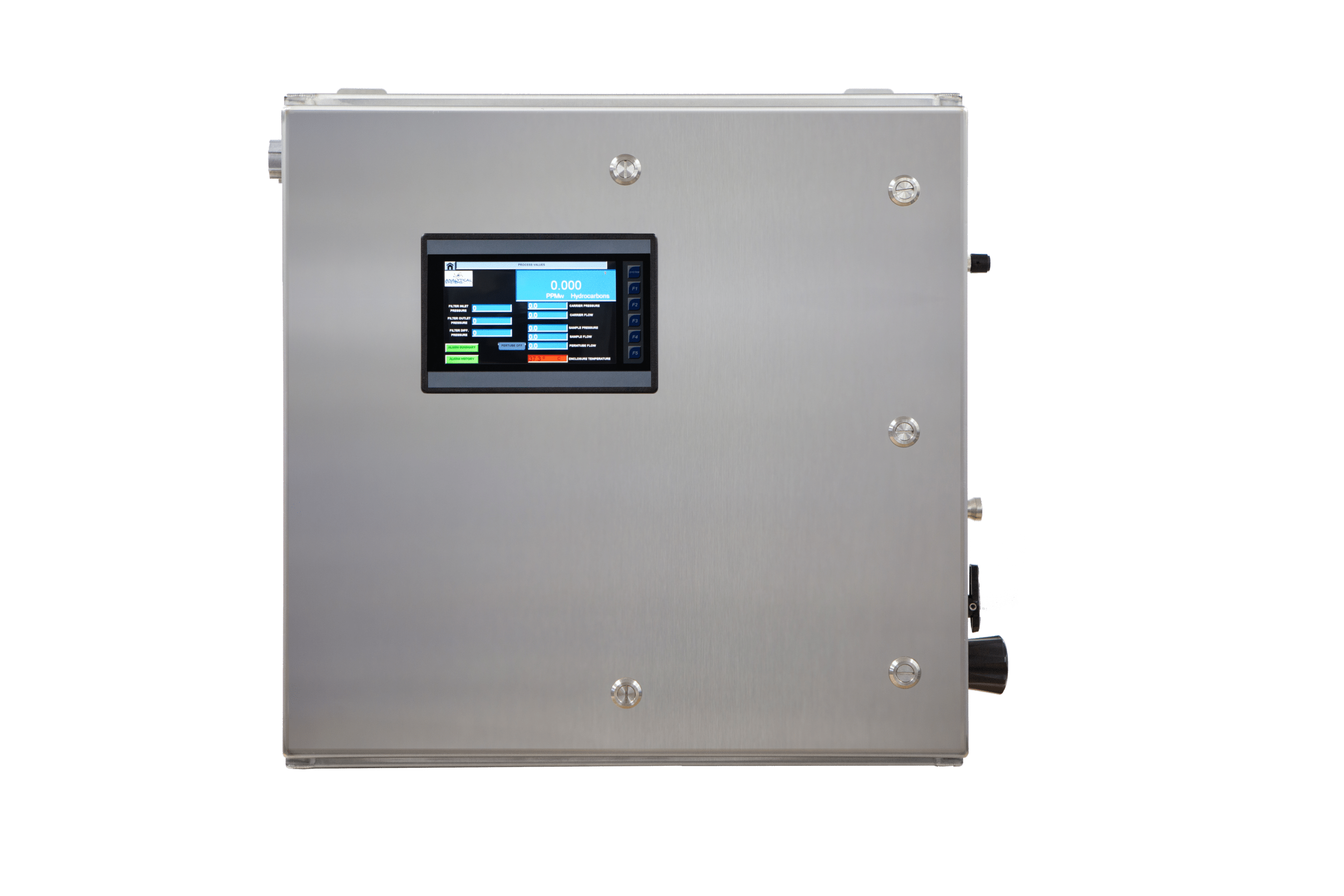

Dependable liquid analyzers for the lab or process including oil in water analyzers, hydrocarbons in water analyzers, H2S in crude oil analyzers, H2S in water analyzers and more.

Reliable and field-proven H2S analyzers, CO2 analyzers, O2 analyzers, and Total Sulfur analyzers for the lab or process.

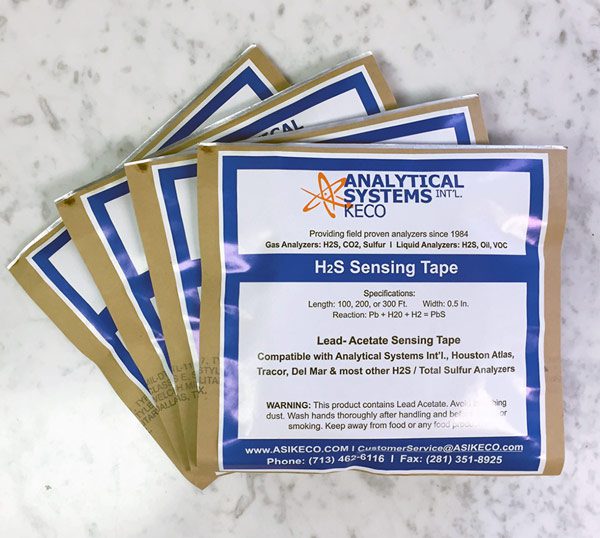

Keep your analyzer performing by purchasing supplies direct online including sensing tape and humidifier solution.